We might obtain a fee while you use our affiliate hyperlinks. Nevertheless, this doesn’t impression our suggestions.

The most important profit: much less sanding.

Massive Slice, Massive Blade

If you’re reducing the again off a giant field, your finest wager is to make use of a 1/2″ 4 TPI (Tooth Per Inch) hook-tooth blade, and information the minimize with a fence. This blade is the widest that the majority 14″ bandsaws can deal with. Its further width helps stop the blade from bending backwards and twisting, which may end up in a bowed minimize. This blade’s extra-deep gullets have loads of room for carrying away sawdust, which additionally helps stop a bowed minimize. A fence, after all, assures that the minimize can be straight–which is crucial while you glue the 2 items again collectively in a while.

If you’re reducing the again off a giant field, your finest wager is to make use of a 1/2″ 4 TPI (Tooth Per Inch) hook-tooth blade, and information the minimize with a fence. This blade is the widest that the majority 14″ bandsaws can deal with. Its further width helps stop the blade from bending backwards and twisting, which may end up in a bowed minimize. This blade’s extra-deep gullets have loads of room for carrying away sawdust, which additionally helps stop a bowed minimize. A fence, after all, assures that the minimize can be straight–which is crucial while you glue the 2 items again collectively in a while.

The Workhorse Blade

My favourite blade for reducing curves is a 3/16″ 10 TPI. It cuts a curve as small round as a nickel. Typically I exploit a 1/4″ 4 TPI blade–nevertheless it leaves a coarser floor that requires extra sanding. One advantage of the 1/4″ blade, although, is that it’s extra aggressive. You must go a bit slower with the three/16″ blade, however the outcomes are value it.

My favourite blade for reducing curves is a 3/16″ 10 TPI. It cuts a curve as small round as a nickel. Typically I exploit a 1/4″ 4 TPI blade–nevertheless it leaves a coarser floor that requires extra sanding. One advantage of the 1/4″ blade, although, is that it’s extra aggressive. You must go a bit slower with the three/16″ blade, however the outcomes are value it.

Each blades require cautious setup, significantly with ball bearing guides. The entrance fringe of the guides must be positioned a hair behind the blade’s gullets, so the blade’s tooth received’t contact the guides. Rounding the again of the blade with a dry oilstone will assist the blade negotiate tight curves.

For Tight Curves, An Additional-Small Blade

When a field requires curves which can be smaller than the radius of a nickel, I take the time to change to a 1/8″ 14 TPI blade. It could possibly minimize curves right down to a 1/4″ radius.

When a field requires curves which can be smaller than the radius of a nickel, I take the time to change to a 1/8″ 14 TPI blade. It could possibly minimize curves right down to a 1/4″ radius.

A blade this small isn’t simple to arrange with standard information blocks, until you’re utilizing phenolic Cool Blocks. Cool Blocks received’t harm the blade’s tooth, so you may set the blade proper in the midst of the blocks.

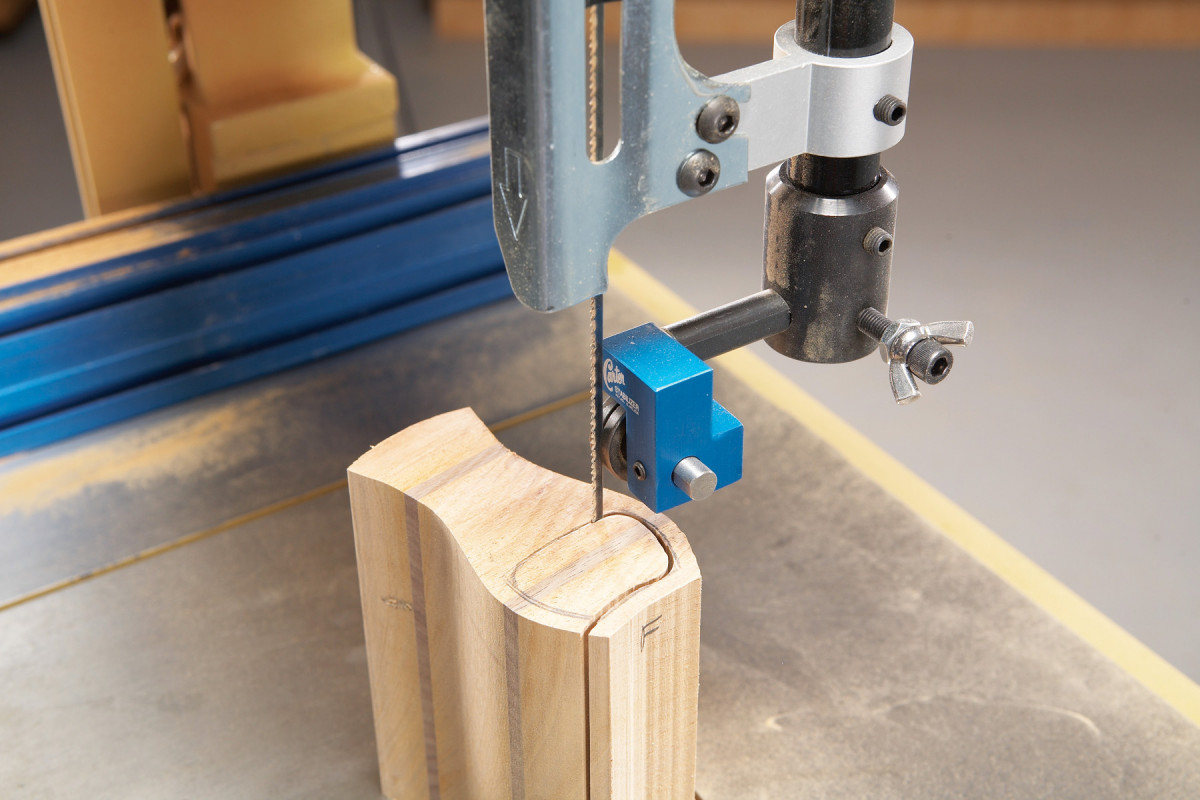

I developed an alternate information system, known as the Carter Stabilizer, for 1/4″ and smaller blades. It briefly replaces the guides in your noticed and could be very simple to put in. The Stabilizer is basically a thrust bearing with a groove down the center. If you set it up, you spring the blade ahead a bit, so the blade stays seated within the groove. Simply again off the decrease bearings, and away you go.

Clean Joints with Sandpaper

Earlier than you glue elements collectively to re-build a field, sand their edges on a full sheet of 80 grit sandpaper. It will make the sides completely flat, which helps make the joints invisible.

Earlier than you glue elements collectively to re-build a field, sand their edges on a full sheet of 80 grit sandpaper. It will make the sides completely flat, which helps make the joints invisible.

I put the sandpaper on the forged iron wing of my tablesaw and safe it with Gorilla Tape so the paper doesn’t buckle or shift. I attempted masking tape and duct tape, however they don’t maintain as nicely. These things does the trick.

Save Elbow Grease

The quickest approach to clear up the bandsawn surfaces of a field is to make use of a mix belt/disc sander. It doesn’t matter what measurement it’s–a benchtop mannequin works positive.

The quickest approach to clear up the bandsawn surfaces of a field is to make use of a mix belt/disc sander. It doesn’t matter what measurement it’s–a benchtop mannequin works positive.

Use the flat belt for convex curves. For the smoothest outcomes, help your work on the machine’s work desk. For concave curves, use the belt’s spherical nostril. Be very cautious, although, and use solely positive grits and lightweight strain to keep up management as you sand.

Felt Makes the Distinction

I line the within of a bandsaw field with adhesive-backed felt. It makes the field’s items nest collectively significantly better, as a result of the felt’s thickness is nearly equal to a blade’s kerf. The wooden you lose by sawing is made up for by the felt. Felt additionally makes drawers glide like butter. Adhesive-backed felt is out there at many craft shops, and is simple to chop with a pair of scissors.

I line the within of a bandsaw field with adhesive-backed felt. It makes the field’s items nest collectively significantly better, as a result of the felt’s thickness is nearly equal to a blade’s kerf. The wooden you lose by sawing is made up for by the felt. Felt additionally makes drawers glide like butter. Adhesive-backed felt is out there at many craft shops, and is simple to chop with a pair of scissors.

Use a Sub-Desk

Typically the cuts don’t come out sq. when making small items. I discovered this out the laborious approach in the future, when a really small drawer turned out tapered from entrance to again. I found that the issue wasn’t my setup or approach.

Typically the cuts don’t come out sq. when making small items. I discovered this out the laborious approach in the future, when a really small drawer turned out tapered from entrance to again. I found that the issue wasn’t my setup or approach.

The issue was the noticed’s throat plate. It wasn’t stage with the noticed’s desk, and, being plastic, had some give in it, so the workpiece leaned into the blade.

I solved this drawback in a rush by grabbing a chunk of plywood to cowl the desk. I minimize a kerf to the plywood’s heart and clamped the plywood to the desk. Accomplished deal–this made a wonderfully flat work floor.

To guard my fingers, I held the piece in a small handscrew. I minimize notches within the handscrew to assist maintain curved items.

Product Suggestions

Listed here are some provides and instruments we discover important in our on a regular basis work across the store. We might obtain a fee from gross sales referred by our hyperlinks; nevertheless, now we have fastidiously chosen these merchandise for his or her usefulness and high quality.