We could obtain a fee once you use our affiliate hyperlinks. Nevertheless, this doesn’t influence our suggestions.

Photo voltaic kilns used at The Residence Store in Charlotte, Mich. Two 16′ kilns are joined on the center by a 4′-section for sticker storage. The top wall is opened with the door to the left and the principle panel is quickly leaning towards the skin.

An economical and environment friendly technique to take inexperienced boards to usable lumber.

The photo voltaic drying kiln is probably the most cost-effective means for the craftsman to get high quality boards for woodworking from inexperienced lumber. Right this moment there are numerous band noticed operators chopping boards from timber that develop in abundance in a lot of America. The photo voltaic kiln is the hyperlink between this useful resource and the store.

A wooden kiln is any house used for controlling warmth and humidity the place lumber is dried. The photo voltaic drying kiln harnesses the free vitality of the solar. It operates on the common cycle of day and evening to stop wooden stress that may wreck lumber in different techniques. The size of the unit at 1,000 board-feet (bf) capability, plus the straightforward construction and inexpensive price of working a fan, makes this photo voltaic kiln sensible for the house craftsman or small skilled store.

The Fundamentals of Drying

Evaporation from the floor of lumber happens when surrounding air picks up the water. The capability of air to carry water relies on temperature. That is expressed within the time period “relative humidity,” the place humidity is the diploma of saturation in a quantity of air, and the quantity is relative to the temperature. When temperatures fall, moisture from saturated air precipitates. When temperatures rise, the air can maintain elevated quantities of water, making it successfully dry air. Maintain on to this final assertion as a result of it’s how a kiln works.

To offer an instance of relative humidity at work, take our houses in winter. Air passes out and in of the conventional house each one-half to 3 hours for a whole air change. Exterior air at 30° Fahrenheit (F) at a cushty 60 p.c relative humidity comes inside the place it’s heated to 70° F and is 20 p.c relative humidity, due to the capability of hotter air to carry extra moisture. This phenomenon is much more at work at larger temperature ranges. The interval from 70° F to 120° F sees a 10-fold improve in moisture-holding capability, which is the vary wherein the photo voltaic drying kiln works. The ambient air on a scorching sticky day in summer season at one hundred pc relative humidity with little capability for drying turns into desert-dry air of 10 p.c relative humidity when the solar heats it to 120° F contained in the kiln.

One other working precept is the day by day cycle of the solar’s vitality shutting off at evening. That is key to the trouble-free operation of the kiln. The hazard inherent in normal hot-air dryers is the stress in wooden on account of floor shrinkage earlier than core areas can dry. Such stress not solely warps lumber, it’s the reason for “case hardening,” which we encounter when sawing a board that can bind the noticed blade. Within the excessive, it may tear the core aside in a situation often known as “honeycombing.”

Within the photo voltaic kiln, the boards have an opportunity to “normalize” on daily basis – what I like to think about as smoothing out the variations in moisture ranges all through the wooden. Due to this day by day cycle, you would not have to observe the progress of drying to be sure you have good outcomes. Nature does it for you. A phrase of warning: Should you incorporate methods of shortening the drying time by having drying go on 24 hours a day, consideration have to be given to the influence it’ll have on boards as a result of that then erases the normalization interval.

Do You Want a Kiln

Who wants a kiln? What are the opposite choices for drying small a lot of boards?

A woodworker referred to as for recommendation on drying field alder lumber lower into 4/4 x 6′ boards. Earlier than giving him the rundown on photo voltaic kilns, I checked out whether or not he wanted one in any respect. The amount he had was about 200 bf, and of that it was the wooden with distinctive reddish markings that he was most serious about drying.

Initially he hoped that I might have room to dry it for him. The reply to that query is nearly all the time “no.” It is extremely tough to mix outsiders’ small tons into present drying schedules. You’ll be lucky in case you ever discover this to be a chance.

Accordingly, with the small amount concerned, and no quick time constraints, he may dry them at house. Understanding what it takes to dry lumber will open up on-site prospects. That is what it’s essential to do:

• Discover a web site with a temperature rise of 10° to twenty° F or extra above ambient air for part of the day.

• Separate the boards to permit for equal drying on all sides.

• Present for air circulation.

• Wait. It takes from a month to a 12 months relying on thickness, species and optimum circumstances.

Take into consideration an area the place it will get scorching, just like the house above your storage, the attic, a barn loft, and so forth. Your house through the winter will serve the necessity, since that is, in spite of everything, the surroundings wherein furnishings exists. There’s a truthful quantity of moisture given off within the quick preliminary lack of free water which may greatest be performed outdoors earlier than house drying. Your store can serve your drying wants you probably have the house. In winter, my store serves to complete off wooden that can’t dry within the photo voltaic kilns, as we warmth the store most days with a wooden range.

Boards are greatest stickered utilizing dry 1″ sq. sticks that optimize air stream between layers. However sticks ¾” thick will work virtually as effectively. The important thing factor is to maintain the stack slim and the boards spaced large aside when relying on pure air stream. By tying into the constructing for assist (C-clamp a strut to a stud as an example), it’s doable to make a stack one board large. Should you can rig up a typical field fan for air stream that might be greatest.

The last word in pure air stream is to face particular person boards on finish. The subsequent greatest is standing them on edge. The drawback right here is the opportunity of warpage in drying, in addition to working out of house to retailer them.

Hold the fundamentals in thoughts and you will discover locations already out there. Crucial act of all is to do it promptly. Hold it easy, however do it.

Construct Diagrams

Constructing the Photo voltaic Kiln

Constructing the Photo voltaic Kiln

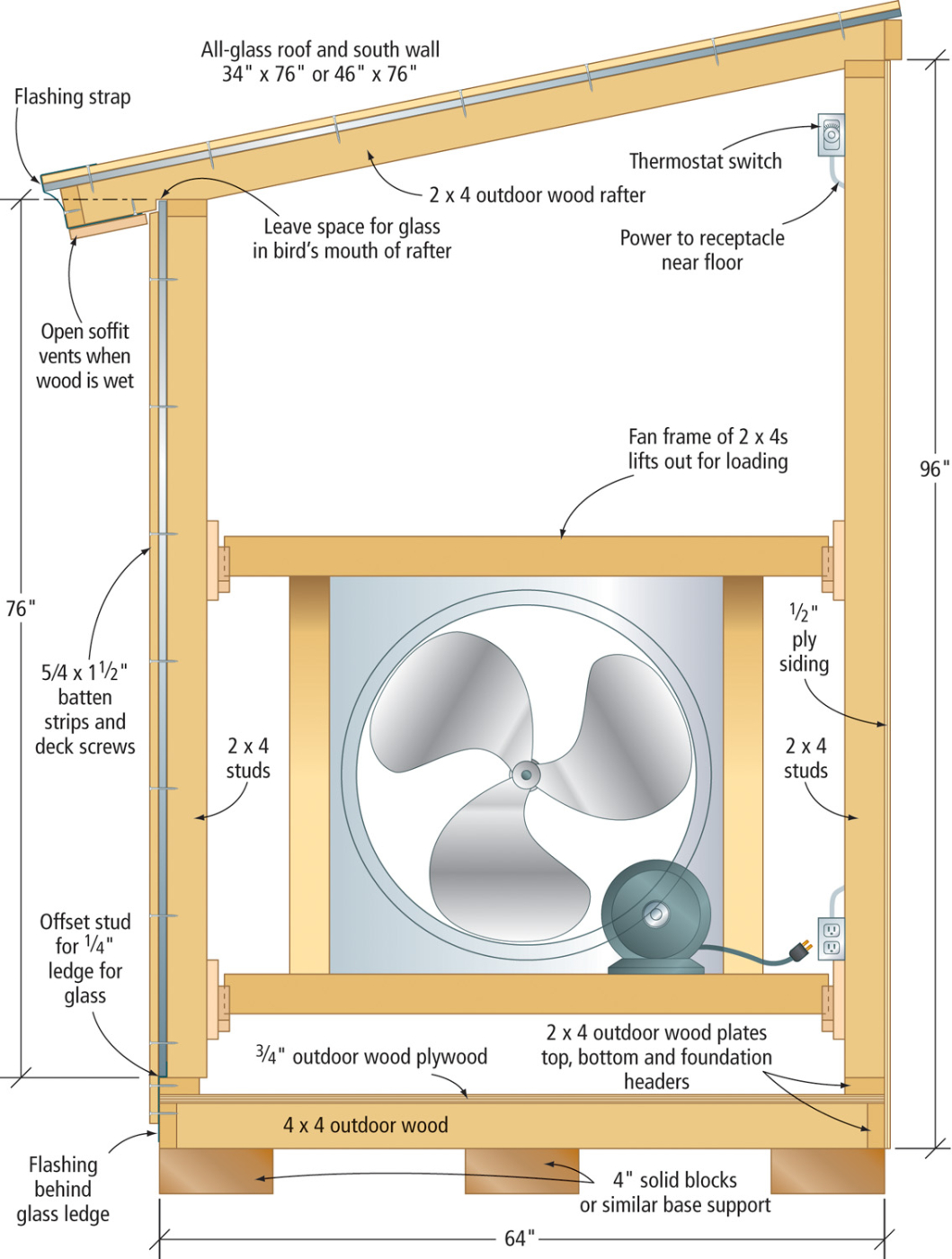

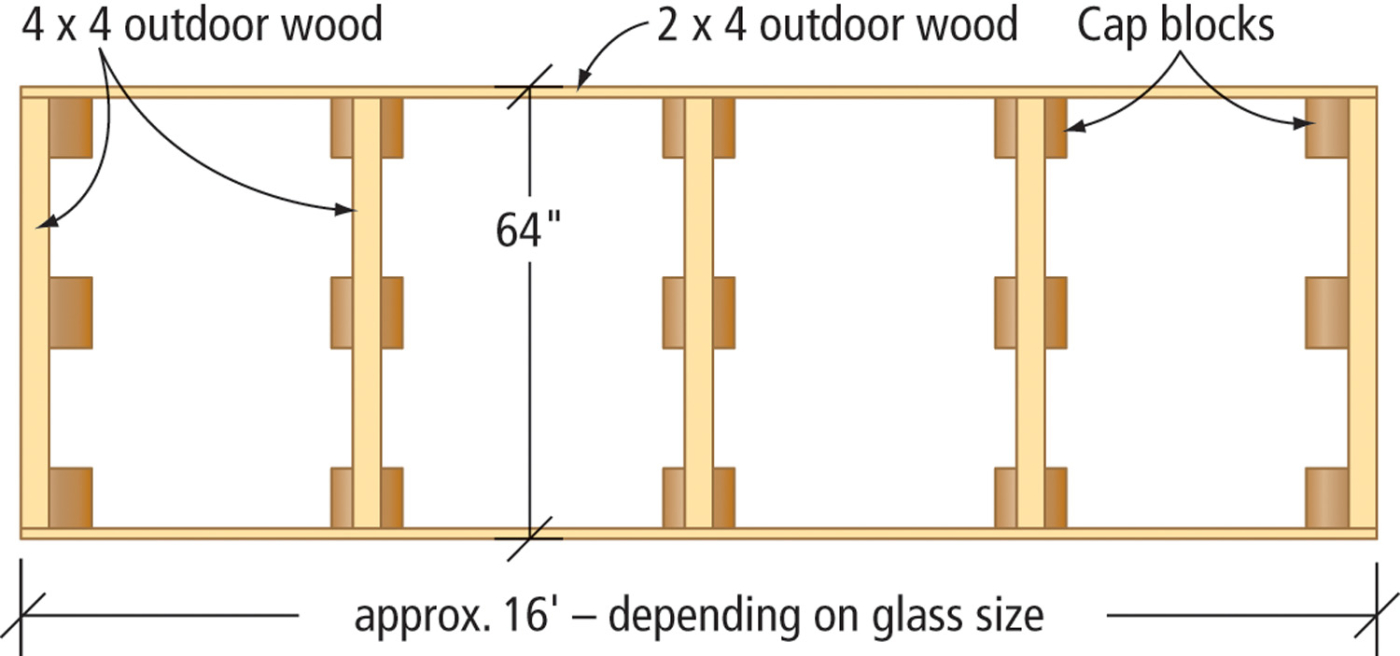

The kilns utilized in our enterprise of offering wooden to craftsmen who make Shaker oval containers have a capability of 1,000 bf to 1,500 bf of lumber. To offer scale to this quantity, 500 bf of dry hardwood boards weighs a couple of ton, or a superb sized pickup truck load. Every kiln is a constructing large sufficient to carry a 4′-wide stack, and lengthy sufficient to suit the longest logs you might be prone to have sawed. Our boards are 12′ lengthy and the kiln is 16′, which permits for the fan on the finish. You possibly can adapt the scale you construct to fit your chopping wants.

The window wall and roof make use of available salvaged sliding door glass panels, that are 76″ lengthy. Every bit of glass lands on a rafter or stud and is held is place by a batten. The top of the rafter batten has a strap to stop the glass from sliding.

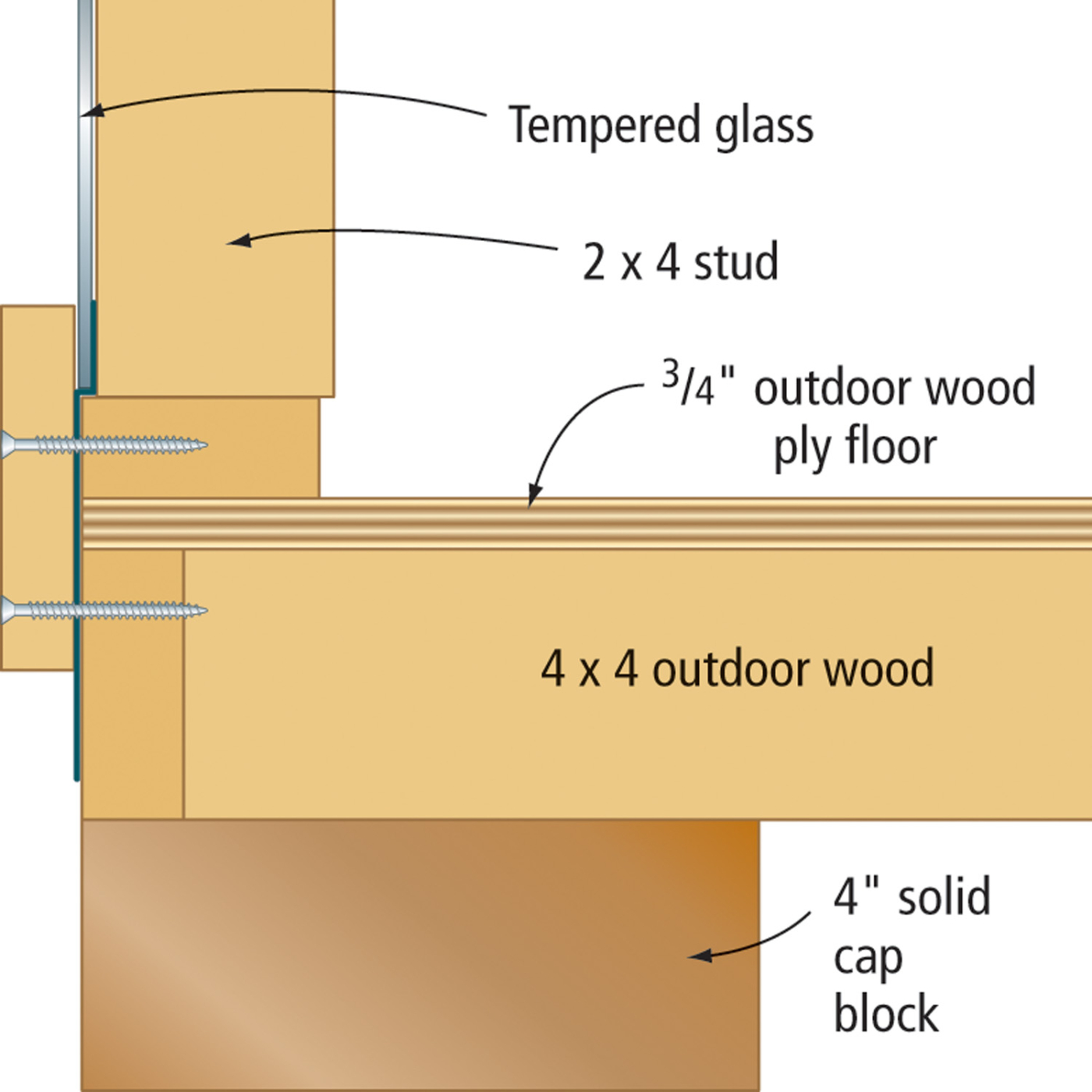

The development makes use of normal 2 x 4s, 1⁄2” plywood sides, a 3⁄4” plywood flooring and 4 x 4s and cap blocks or quick posts for a basis. The south wall and roof are created from recycled tempered glass of the type utilized in sliding patio doorways. These thermopane models have a nasty behavior of creating air leaks within the seals, which fogs the glass. Alternative is widespread, and used glass is available from these within the window enterprise. The situation of the seal doesn’t have an effect on our use, as a result of single-layer glass is used. To separate previous thermopanes, run a utility knife across the edge to elevate the glass off the seal. Don’t clear off the remaining rubber seal on the glass as it’ll make for a greater set up. We don’t use double-pane glass as a result of the night-time insulating qualities should not mandatory because the kiln shuts down anyway, and within the day there can be a 10-percent solar loss because of the second layer of glass.

The plans present building particulars for the constructing. Earlier than constructing, nevertheless, you have to acquire the recycled tempered glass panes. Their dimension will decide the spacing of studs and rafters, in addition to the precise total dimension of the constructing. The usual thermopane in 8′-patio doorways is 46″ x 76″, and in 6′-patio doorways, 34″ x 76″. Both dimension will work as it’s the 76″ size that can span the roof. The perimeters of the glass must be supported on 2 x 4 framing, which will probably be adjusted in line with glass dimension.

The underside of the wall home windows rests on a 1⁄4″ ledge within the framing. Aluminum flashing retains water out whereas the glass is held in place by a block, on this case scrap Corian left over from a countertop set up.

I’ve discovered from dismantling older kilns that using out of doors wooden will add years to the constructing. Rafters, wall plates at prime and backside, flooring plywood, and basis framing want to resist water. The straightforward wood-batten and deck-screw fastening of glass on the roof offers sufficient service, however because it doesn’t stop some water leakage, the framing beneath must be rot resistant.

A phrase about air infiltration is so as. Don’t be concerned with stopping up all of the cracks and sealing the doorways. This constructing works effectively with the extent of building used for a hen home. Some air stream from completely different locations within the constructing is regular.

Two areas of structural concern for glass attachment are the foot ledge on which the south wall glass rests, and the straps over the eave finish of roof glass. The plans present using flashing to cowl the shelf that helps the glass sheets for the wall. Observe instructions (proven within the drawings in addition to the picture under) to attain the 1⁄4” step within the flashing. The roof glass provides an attention-grabbing instance of glass dynamics. Glass expands and contracts with temperature modifications. Each time it does, glass tries to creep down the roof slope. To counter this, a strap created from a double fold of flashing 11⁄2” x 14″ is screwed into the rafter across the eave finish. If these screws enter the eave board solely and never the rafter, your entire board may be pushed out.

Bending the aluminum flashing used within the 1⁄4″ ledge on which the window wall glass will relaxation. The first step was to make a proper angle within the flashing. Right here, the ultimate bend is facilitated by a board with a 1⁄4″ rabbet sawn in it and clamped to the bench.

The kiln works when air is warmed, circulated by means of the stack of boards, and a portion vented from the constructing laden with moisture. The glass south wall and roof present photo voltaic vitality for heat. The adjustable soffits alongside the eaves present escape for moisture. Air circulation throughout the kiln is supplied by the fan. There may be an excessive amount of resistance to air stream inside a stickered pile of boards. To beat this resistance, a high-volume fan is required. A 30″-attic fan that operates within the 5,000 cubic toes per minute (cfm) vary can do the job. Models can be found from low cost builders’ provide for $220.

The fan mounts on a detachable 2 x 4 body on the opening finish of the kiln. The body matches into holding slots so it may be lifted out for loading or servicing. The ability is switched by means of a thermo swap of the kind utilized in farm silos. This will probably be set for seasonal nighttime temperature, which in Michigan is 70° F in the summertime and 50° F within the spring and fall.

Earlier than loading, the tip of the kiln is opened by a hinged door panel and unscrewing a 4′-wide fundamental panel. The 30″ fan is being eliminated to provide entry.

With this temperature swap in place, the fan operates through the day solely. It switches off at evening when there’s little temperature benefit which permits the boards to equalize their inside moisture ranges.

Working the Kiln

Stacking lumber on this kiln is a hand operation as a result of we’re too small a enterprise for using a forklift. Had been mechanical loading desired, then a beam of two 2 x 12s throughout the highest of the again wall would enable for removing of all of the again plywood panels and helps when loading from the rear. As it’s, we use a cordless drill to unscrew the plywood part within the again the place a person stands so as to add sticks to the layers of boards throughout loading.

The house on the prime of the window wall is opened by eradicating the soffit panels. It’s when inexperienced wooden is first launched that this venting of moisture-laden air is important. Later within the drying cycle, the soffit is screwed shut to extend temperatures within the kiln, whereas moisture is dissipated by means of small cracks within the construction’s easy building.

It additionally makes it bearable to work in there on a sunny day. The big finish panel is secured and opened the identical means. (The 16″-wide finish panel is hinged to afford entry to examine as drying progresses.) Deck screws positioned 18″ to 24″ aside has not been an issue for entry the three or 4 occasions a 12 months it’s wanted. It needs to be famous that the tip panel is structurally essential to preserve the constructing from sagging, so preserve it screwed in place besides when loading.

Right here, we substitute the fan, which will probably be plugged right into a receptacle whose energy is managed by a thermostat. The top wall is closed through the use of drywall screws to safe the door and the principle finish panel.

When stacking lumber, use dry sticks 1″ sq. by 4′ lengthy. Scraps lower whereas milling is usually a supply of sticks, however moist wooden sticks could cause mould progress. Higher to take a position the time to make ones which might be saved shielded from rain when not in use. Ours are 3⁄4” thick by 1″ large slightly than the total 1″ squares of business operators. When loading, preserve the sticks in line, one above the opposite, to keep away from bending unsupported boards with all of the lifeless weight of the load above. Spacing is three toes aside. You have to about 200 when filling the kiln.

Area the boards a number of inches aside for air stream. We’ve got experimented with alternative ways of shifting air, and easily having a large-volume fan at one finish blowing by means of the stack spaced with the perimeters of the boards 1″ to 2″ aside works. Nevertheless, we frequently go away an extra chimney 6″ large up the center within the first half of the load. When drying is full, unsticker the pile, as wooden can simply reabsorb moisture throughout poor drying months.

Everybody asks how lengthy it takes to dry lumber in a photo voltaic kiln. There are lots of solutions, starting from 4 weeks to 6 months. Climate, species of wooden and thickness of boards are the main elements. Evaluating photo voltaic drying with different techniques, the evening shutdown interval means prolonged drying occasions for any dimension or sort of stack. The season of the 12 months will predictably come as a significant factor. Right here in Michigan, the kilns work successfully March by means of October. Throughout winter months, drying all the way down to 12-15 p.c moisture content material (MC) will happen, nevertheless it takes hotter circumstances to attain full drying. After we want boards dry in winter, we unload a small quantity, like one-fourth of a complete kiln, into the store (which is heated on daily basis). These are stickered utilizing two strange 24″ field followers to complete the drying.

The 2 different elements affecting drying occasions are the species and thickness of the lumber. Softer woods dry in half the time of oak and maple. Because the thickness will increase, so does the size of time, and at the very least proportionately: twice the thickness, twice the drying time, or extra.

Some forms of wooden are susceptible to warping. Elm is considered one of them, particularly when knots are current. Right here, elm boards had been set on prime of the kiln load to dry. With out the burden of stacked boards on prime, that is what occurred a month later. It was so unhealthy, one needed to chortle! I by no means noticed something prefer it in 20 years. You possibly can learn all of the studies, however on the finish of the day, expertise will probably be your trainer.

All of this implies it’s essential to have a moisture meter with the intention to function a drying kiln. Additionally, examine periodically whereas unloading, as the highest layers dry before decrease ones do. Lignomat makes a line of meters, and the smallest unit, the mini-Ligno, is what we use. The regional requirements differ a bit relying on native circumstances. Right here in Michigan, boards utilized in furnishings making are 7 p.c MC. Air drying will obtain 14 p.c MC after a 12 months. The rationale for utilizing a kiln is to complete the drying, shorten the time, and keep away from defects from climate publicity, mould and bugs.

The advantages of those kilns stay excellent for the small operator. They supply the means for changing available inexperienced lumber into completed inventory. The low funding and small working prices make it doable to simply start with one kiln, and add one other if wanted. This will overcome the slower drying occasions inherent to such a system. Couple these economics with the self-regulating drying cycle, and you’ve got a user-friendly system for the craftsman with a small store.

Product Suggestions

Listed below are some provides and instruments we discover important in our on a regular basis work across the store. We could obtain a fee from gross sales referred by our hyperlinks; nevertheless, we now have fastidiously chosen these merchandise for his or her usefulness and high quality.