We could obtain a fee if you use our affiliate hyperlinks. Nevertheless, this doesn’t influence our suggestions.

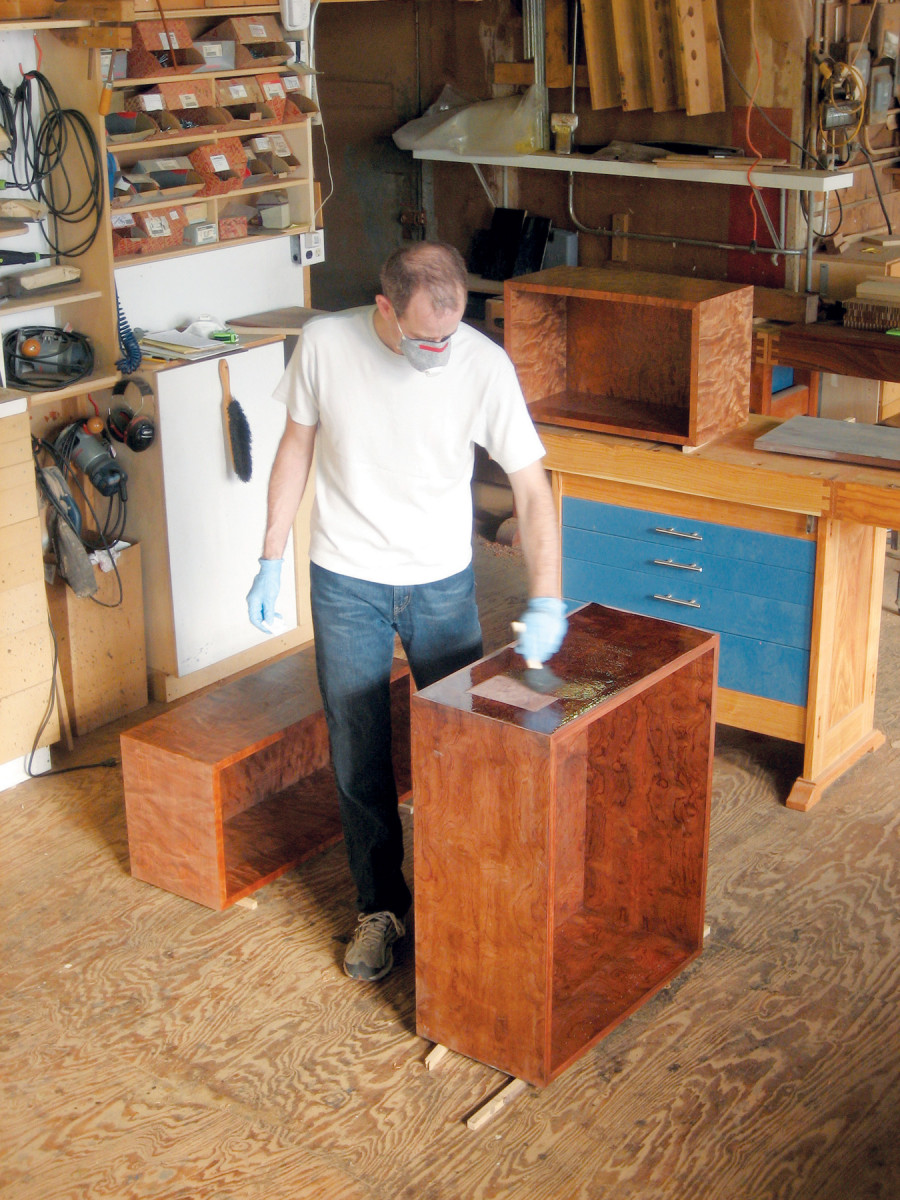

Photograph 1. Brushing a end is far simpler should you can apply a thinned coat on horizontal surfaces earlier than meeting. All glue joints, like these mortise and tenons, ought to be masked off.

A Disposable Brush And A Few Rags Construct An Superior End.

Ending is a difficult facet of woodworking. There are various ending supplies and strategies of software; inside a single piece there could also be a number of situations requiring completely different approaches. It’s one factor to get a pleasant end on a small flat pattern board however what about inside corners, vertical surfaces, curved areas, skinny edges and framed panels? It might be tempting to consider spraying as a cure-all however spraying comes with its personal set of issues and nonetheless requires numerous effort to get an expensive floor.

This text presents a method that will help you apply a end by hand, utilizing solely a brush and a few rags. The sequence requires a skinny coat or two of polyurethane, scuff sanding and ultimate coats of a wiping gel varnish to take away the sanding haze.

The purpose is a end that seems degree and clear, exhibits the pores and texture of the wooden, and feels very clean (even on inside corners). I like a barely shiny sheen. If it has been utilized and dealt with correctly, it is going to seem as an integral a part of the floor and never like a plastic movie.

Hand making use of a end has many qualities in frequent with hand software work. The method is quiet, meditative and advantages from a eye for element. It additionally requires follow to excellent.

Supplies:

- Brushes: 3” foam brushes with wooden handles. Reduce about 1” off the tip of the deal with, sand the sting and so the comb could be saved within the quart can of end. This eliminates using solvents to scrub the comb.

- Polyurethane: I exploit semi-gloss Minwax Quick Drying Polyurethane for the interiors of cupboards and gloss for the surfaces on the skin.

- Thinner: Naptha is healthier than paint thinner because it evaporates quicker. The purpose is to skinny the poly so that it’ll stream out higher with out extending the drying interval an excessive amount of.

- Gel Varnish: Bartleys Gel varnish handles nicely and solely is available in satin.

- Sandpaper: You will have stearated sandpaper in 400, 600 and 800 grit.

- A felt block for backing your paper.

- Cotton or paper wipes. I exploit Taskmate/Brawny Industial.

- Japan drier, out there at most paint shops.

Apply The Polyurethane Varnish

Begin by sanding every thing to 180-grit then moist the sanded surfaces with water. After it dries, scuff sand the raised grain with a felt block and 220-grit paper. Mud or vacuum the mud. The floor doesn’t must be spotless as a result of the scuff sanding between coats will clean out any vagrant mud within the end. I don’t trouble with a tack rag.

I fully pre-finish all the inside surfaces and partially end the outside surfaces of a cupboard earlier than meeting. Pre-finishing lets me work on flat, horizontal surfaces with out having to brush into an inside nook (Photograph 1). Mortises, tenons and all glue surfaces ought to be taped off. I exploit fundamental masking tape and a utility knife to trim the tape after it’s utilized. I end one floor at a time, letting it dry fully earlier than turning it over to complete the other facet.

The primary coat is polyurethane that’s been thinned till it’s extra like water than syrup (normally about 20% naptha by quantity). The precise quantity is just not that necessary. What you need is a coat that flows out and stays moist when you brush. Add 1/3 of a capful of Japan drier to assist pace the curing.

A pure bristle varnish brush requires a lot of solvents to take care of. I merely use a disposable foam brush and retailer it within the partial can of varnish I’m utilizing. One brush will final for all of the coats I apply.

Photograph 2. Brush a fringe of end on the floor of a panel leaving a dry edge to forestall drips. Sticks elevate the panel and facilitate working the sides.

Working with foam brushes requires some getting used to. Dip the comb midway into the end, let it drip again into the can a bit and shortly transfer the comb to the work piece with out dripping. With follow you’re going to get a way for the correct amount of end to load into the comb.

Photograph 3. Fill within the perimeter. Lay out an excellent, moist coat of polyurethane over all however the very edge. No want to fret about brush stroke route but.

Foam brushes are inclined to push a small puddle of end in entrance of them. To keep away from pushing the end over an edge, I begin by making use of a fringe of end roughly 1-in. from the panel edge, (Photograph 2). Then, work the end forwards and backwards to fill within the center (Photograph 3). Make sure to preserve shy of the sides.

Photograph 4. Brush the dry border. Maintain the comb frivolously, barely overhanging the sting. Make the comb stroke parallel to the sting.

Subsequent, brush the dry border with a brush that’s simply loaded sufficient to moist the wooden however not sufficient to go away drips on the sting (Photograph 4). Return over the complete floor, in any route, to maneuver the end round and create a skinny even movie with no puddles or dry patches.

Photograph 5. The ultimate strokes are made with the grain. Maintain the unloaded brush frivolously with simply the tip touching and are available to the floor on a protracted low angle like a airplane touchdown. Use a raking mild supply to examine for puddles or dry spots.

“Graining” is the time period I exploit to explain the ultimate brush strokes made parallel to the grain (Photograph 5). Begin the strokes simply in from the sting and proceed all the way in which off or previous the other finish. The one downward strain ought to be from the burden of the comb; you’re simply frivolously smoothing the end within the route of the grain and don’t wish to push end over the sting.

The raking mild ought to reveal a skinny, even and degree coat of end with the comb marks beginning to stream out and disappear. In the event you see puddles or dry spots you may transfer the end round with the comb after which re-grain with mild strokes.

Photograph 6. End the sides of inside elements by brushing on the end then wiping it off instantly. Use a tightly folded wipe or rag to keep away from disturbing the highest end. Make sure to clear the underside of the sting as nicely.

At this level I sort out the sides of the within elements. I brush poly on these edges and wipe it off immediately with a fabric (Photograph 6). This leaves a skinny movie of varnish that received’t sag or drip. The skinny movie provides sufficient safety for edges which can be inside a cupboard (like a shelf). Use your raking mild to examine for a ridge of end that will have been pushed onto the highest. Re-grain with a light-weight brush stroke on the highest if mandatory.

For exterior edges I help the dried panel vertically in order that I can brush on the now horizontal edge. Use the tightly folded towel to wipe any drips off the pre-finished prime and backside surfaces.

Photograph 7. Curved surfaces will take a look at your abilities. Use a much less saturated brush with a light-weight contact and examine repeatedly for drips or sags. It’s necessary to catch them early to allow them to be brushed out earlier than the end will get sticky.

Curved elements are brushed with a drier brush (Photograph 7). Dip the comb tip within the end and brush frivolously with the comb held in a extra vertical place. Restrict your brushing space to at least one face and brush out a skinny even coat. Wipe off the adjoining faces to take away any drips.

Photograph 8. Scuff sand with 400-grit paper on a felt block after the primary coat has dried in a single day. The purpose is to not take away materials, simply knock off the raised fuzz and make the floor really feel clean.

If you find yourself finished, clear the rim of the can, drop the comb in it, maintain a deep breath for a minute and exhale into the can proper earlier than inserting the lid on. It will exchange the O2 within the can with CO2; and decrease skinning.

Photograph 9. Apply the gel varnish to all the inside elements with a foam brush. The gel varnish covers up the scratch sample made by the sandpaper.

The subsequent day, scuff sand the seal coat (Photograph 8). A lightweight however complete sanding is all that’s required. Sand very frivolously close to the sides the place the end could be further skinny. The wiped off edges ought to already be clean. In the event you discover you could sand out somewhat fuzz on the sides, use a light-weight contact some folded up 800-grit paper. At this level, I apply 2-3 coats of gel varnish to the inside surfaces solely (Photograph 9).

Photograph 10. Wipe off all of the gel with two rags and two fingers. Get two recent wipes and firmly re-wipe the piece with the grain. Pay explicit consideration to the start and finish of the wiping stroke. Push down exhausting as you permit the board to take away the sticky remnants that stay close to the sting.

Brush the gel on a lot of the half after which smear it over the complete floor and edges with a wipe in every hand. Swap to a brand new set of wipes to take away all the surplus gel varnish (Photograph 10). Any remaining gel will dry to a sticky mess, so get it off now. Use a clear folded wipe off the sides. Take away any vagrant gel from the underside of the half and clear off smudges out of your hand on the highest.

Photograph 11. Apply a second coat of poly to the skin of the cupboards after the interiors are finished and the cupboards are assembled.

With the inside surfaces completed I assemble the case and apply a second coat of poly on the skin of the cupboard (Photograph 11). I solely do one facet at a time, rotating the case to convey a brand new facet horizontal after the earlier facet has dried.

Photograph 12. Wipe up any drips that type on the cupboard edges with a folded towel.

Often I can do 2-3 sides of a case a day. Blankets and padding are necessary to guard the perimeters from injury as you rotate the cupboard. Wipe off any drips that will type on the sides (Photograph 12).

Photograph 13. Calmly sand the outside surfaces with 600-grit paper. Be very circumspect close to the sides. Sand to inside 1/8-in. of the sting after which do mild passes on this sand-free zone, barely letting the block go over the sting.

Wait no less than 2 days for the second coat to dry. Then scuff sand frivolously with the 600-grit to boring out about 30% of the shiny floor (Photograph 13).

Photograph 14. Remaining sanding is completed on the outside surfaces with 800-grit paper and may go away a degree floor. Search for a 90% sanded floor with an excellent sample of small shiny pores if you wipe off the mud.

Repeat with 800-grit paper and the felt block. This time, push down tougher to degree the floor (Photograph 14).

The subsequent step is to make use of a gel varnish to cowl the scratch sample from the sandpaper simply as you probably did with the inside surfaces.

Be aware: The used wipes ought to be individually unfold out to dry when you’re finished.

Subsequent coats of gel will cut back the sanding haze. Often I’ll apply 2 to five coats of gel on prime of the poly to get the end I’m in search of. For my actually particular items and on darkish finishes I’ll polish with 3M’s Imperial Hand Glaze #5990 between the final coats of gel. I hardly ever use wax besides on skinny or satin finishes.

This end sequence can be utilized over dyes and stains however you should be very cautious close to the sides, particularly with dyes. Darkish colours would require extra coats of gel and Hand Glaze sharpening to take away the haze.

Photograph 15. Preserve making use of gel coats on the skin of the case till you get the look you’re after.

Through the years I’ve discovered this strategy reduces the ending course of to manageable steps. When every step is carried out nicely it persistently yields an awesome, trouble-free end (Photograph 15).

Product Suggestions

Listed here are some provides and instruments we discover important in our on a regular basis work across the store. We could obtain a fee from gross sales referred by our hyperlinks; nonetheless, now we have rigorously chosen these merchandise for his or her usefulness and high quality.