Calipers, dial indicators, and peak gauges are sometimes considered machinist’s devices, however in addition they occur to be extraordinarily efficient in a woodshop. Easy to make use of but able to precisely measuring to thousandths of an inch, they’re very good not just for tuning machines but in addition for setting fences and bit heights, assessing blade squareness and bit runout, measuring tenon and mortise sizes, and establishing workpiece thickness.

Some could argue that utilizing machinist’s instruments for working wooden is overkill as a result of wooden strikes, however I disagree. The distinction between a joint that matches correctly and one which’s too free is only some thousandths of an inch. Jointer tables which might be barely misaligned and noticed cuts which might be barely out of sq. result in twisted faces and edges that may make edge-gluing and joinery tough. Use calipers, dial indicators, and peak gauges, and you’ll keep away from these issues. And also you don’t should lay our a fortune to boost the extent of precision in your store, since cheap variations of every of those instruments can be found.

Calipers

|

|

Calipers measure in 4 methods, and utilizing them is a snap in all 4 modes. They’ve acquired two units of jaws. The massive ones take exterior measurements just like the thickness of a tenon or the diameter of a drill bit; the smaller set is used for inside measurements just like the width of a mortise or the diameter of a gap.

To measure depth, you employ the skinny bar that extends from the calipers while you open the jaws. With the bar bottomed out in a gap or mortise and the top of the calipers’ physique contacting the floor of the workpiece, you’ll have your depth studying.

The fourth sort of measurement you may take with calipers—and one which’s usually neglected—makes use of the offset, or step, between the instrument’s fastened and transferring jaws. This works to measure things like the size of a tenon or the depth of a rabbet.

You may select between three types of calipers: vernier, dial, and digital. Every sort performs the identical measurement operations, however I want digital calipers since they provide just a few extra choices. With the press of a button, you may toggle between imperial and metric measurements, and a few fashions even supply fractions as an possibility. As well as, you may zero-out digital calipers at any worth if you wish to take a differential measurement.

Digital depth cease for the drill press

I modified a cheap pair of plastic digital calipers to make a depth gauge for my drill press. I began by slicing off each of the calipers’ small jaws in addition to the massive jaw that’s hooked up to the digital readout. After bolting a block of wooden to the drill press and screwing a bit of aluminum angle to the block, I hooked up the again of the digital readout to the aluminum angle with double-stick tape. I hooked up a second piece of aluminum to the quill of the drill press and bolted the one remaining jaw to that. Because the quill strikes up and down, the massive jaw strikes with it whereas the digital readout stays stationary and shows the place of the bit.

|

|

|

Dial indicators

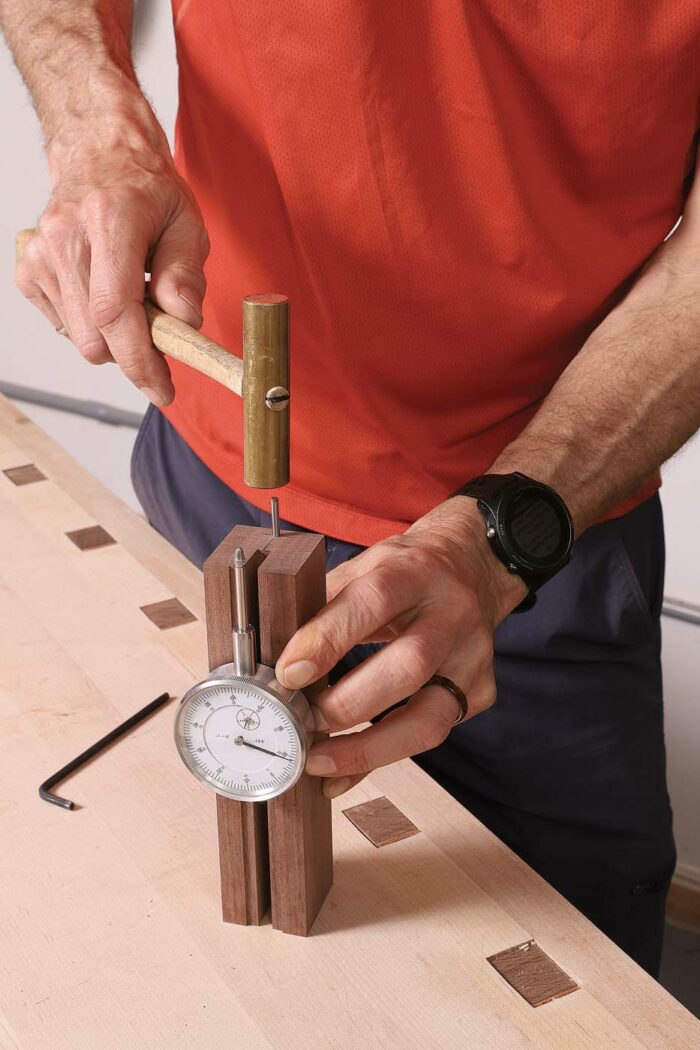

Dial indicators allow you to take correct measurements in a big selection of conditions. They have to be mounted in a holder for many functions, so you might wish to think about shopping for a base along with the indicator. You may as well make specialised holders your self, and some that I’ve made are proven within the pictures.

There are totally different types and resolutions of dial indicators, the most typical being a plunge sort with 1 in. of journey and a decision of 0.001 in. (The comparable metric model has 10mm of journey and a decision of 0.01mm.) Analog and digital dial indicators can be found, and so they each work nicely. I want the analog model for many makes use of, since I discover it simpler to gauge how far a needle is rotating than how briskly numbers are flying by on a digital readout.

|

|

|

Dial indicators work nicely for making exact and managed changes to the fence on a router desk, drill press, or desk noticed. That is helpful while you’re slicing a groove, as an illustration, and after making the primary go it is advisable reset the fence barely. I’ve hooked up magnets to the again of a digital dial indicator, and I exploit it any time I must make small changes to my table-saw fence. When you’ve got a router desk with a fence that doesn’t stay parallel as it’s moved, you may nonetheless use a dial indicator to make exact changes. Mount the indicator on a bit of ply and clamp that to the router desk with the probe touching the fence immediately above the router bit. With one finish of the fence locked in place, it’s a easy matter to pivot the opposite finish till the indicator reads the proper offset from the beginning location.

Shopmade precision sq.

For assessing 90°, a shopmade sq. is typically the best choice.

|

|

|

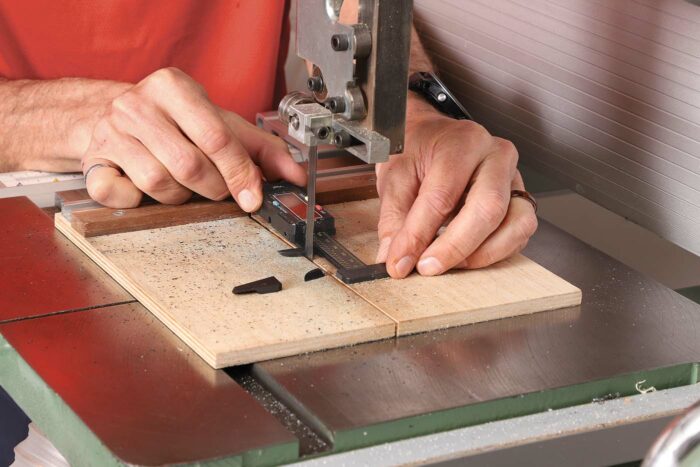

| Excellent sq. for particular circumstances. Whenever you’re bringing a bandsaw’s desk again to 90°, it may be tough to learn the hole between an odd sq. and the bandsaw blade. This system solves that downside. It’s equally helpful on the desk noticed, the place the blade’s tooth will be in the best way of a sq., and on the jointer when returning the fence to 90°. | ||

Make a protracted base for leveling

|

|

|

|

||

Peak gauge

A digital or analog peak gauge is the right instrument to set the peak of a router bit or a table-saw blade. The method is straightforward. If I must rout a groove that’s precisely 3/8 in. deep, for instance, I first zero out the gauge on the floor of the router desk. Subsequent, with the router bit barely decrease than remaining peak, I place the probe so it’s touching the highest of the bit. I then increase the bit, whereas holding the bottom of the gauge flat on the desk, till it reads 0.375 in. Now I’m able to rout.

Incremental peak changes are simply made utilizing the zero button on a digital peak gauge. Decrease the probe onto the highest of the blade or bit and nil out the show earlier than adjusting the cutter up or down till you get the specified offset. If it is advisable decrease the blade or bit, it’s finest to go decrease than required after which increase the cutter to the specified peak. This avoids errors because of backlash within the increase/decrease mechanism.

The extra that you just use these machinist’s devices, the extra functions you will discover for them in your woodshop.

-David Bedrosian works wooden in his basement workshop in Waterloo, Ont., Canada.

Join eletters at this time and get the newest strategies and how-to from Nice Woodworking, plus particular affords.