We might obtain a fee if you use our affiliate hyperlinks. Nevertheless, this doesn’t impression our suggestions.

From the Archives: You don’t need to personal a lathe to make alternative handles that can really feel like an extension of your hand.

From the Archives: You don’t need to personal a lathe to make alternative handles that can really feel like an extension of your hand.

Just a few months in the past I needed to face the disagreeable reality about my chisels. Given to me years in the past by my father, my trusty previous set of Marples bevel-edge chisels had run out of metal. Floor and sharpened to stubs, that they had to get replaced.

Some research into the chisel market revealed a surprisingly massive choice. The essential consideration, it appeared to me, was efficiency – which blades would take the keenest edge and maintain it longest. However after I’d plowed by means of a stack of critiques (not being a instrument metal skilled, I relied on the checks and expertise of others) and narrowed the sphere, I discovered I’d neglected a second essential consideration: handles.

Irrespective of how marvelous the leading edge, if the instrument seems like a billy membership in your hand it’s of little use. A number of of the top-performing chisels had clunky handles, whereas the handles I appreciated greatest had been connected to chisels that didn’t fee so excessive. Marples chisels, whereas not on the high of the league efficiency rankings, had been worth for cash. However as a substitute of the leather-washered, effectively proportioned ash handles of my previous set, they arrive at the moment with slightly billy-clubbish handles of composite or ash. Ultimately, I discovered myself shopping for a number of chisels as a lot for his or her handles as for his or her metal.

The extra I thought of it, the extra this appeared an sad compromise. It was as soon as widespread observe to promote unhandled chisels. Craftsmen purchased the chisel blade then purchased or made a deal with. Is smart – and in the event that they made their very own deal with, it was cheaper. Few, if any, instrument retailers promote unhandled chisels at the moment. However you possibly can nonetheless get one of the best of each worlds. Ignore the deal with and purchase the instrument for its metal or its worth for cash or no matter else appeals to you. Then lower off and change the offending deal with.

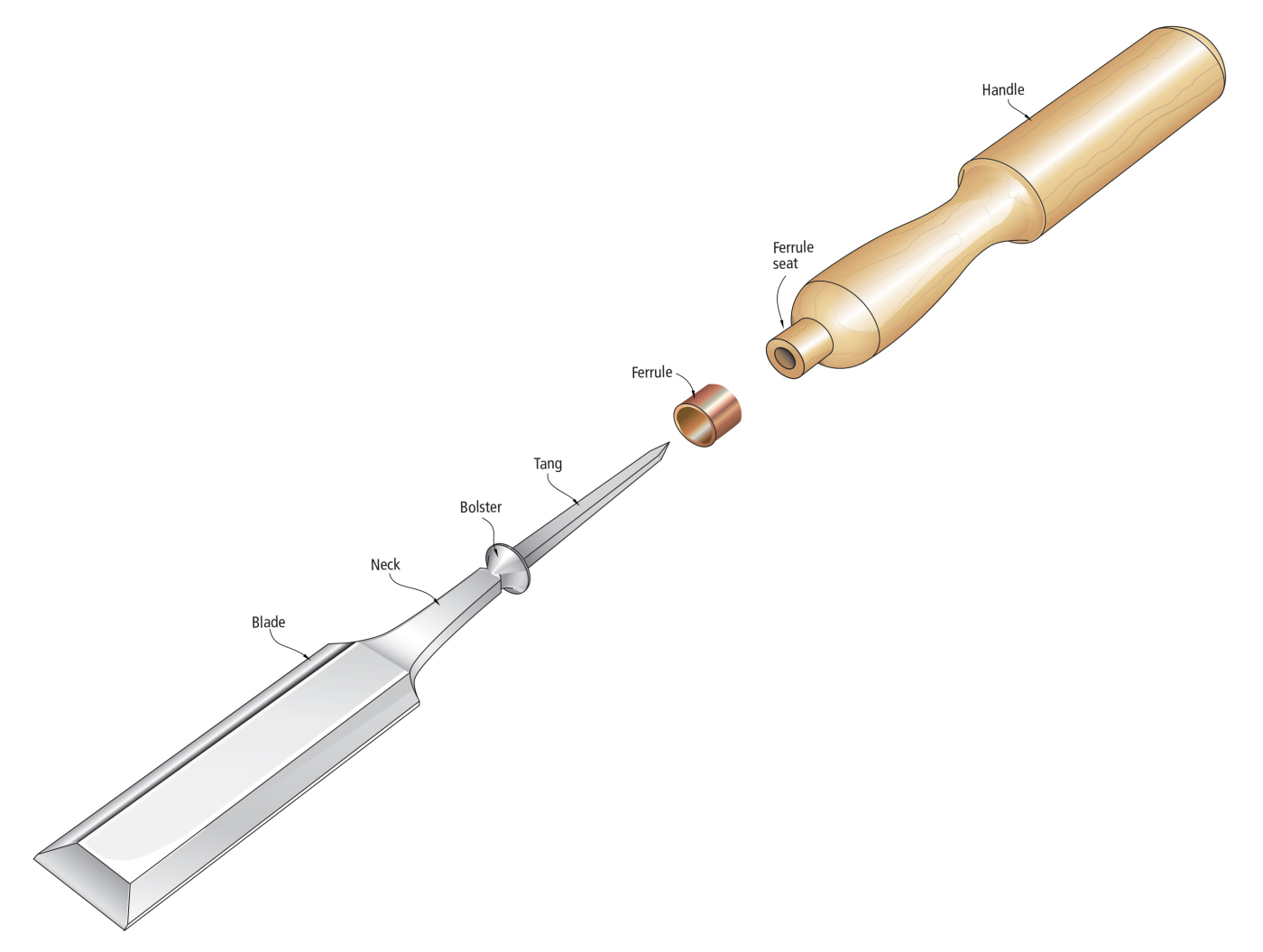

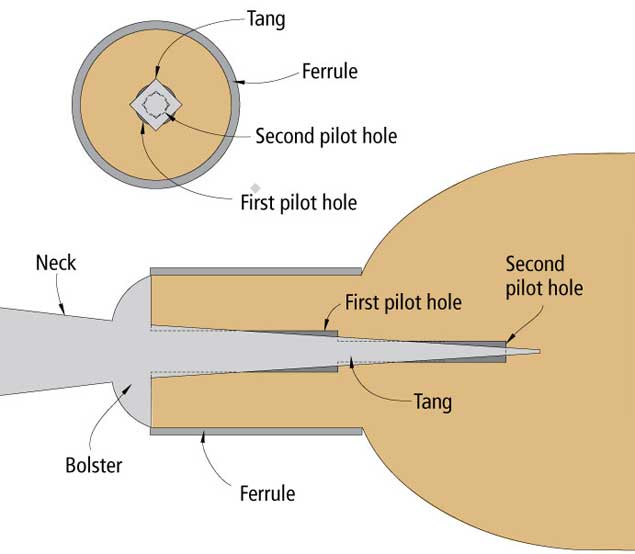

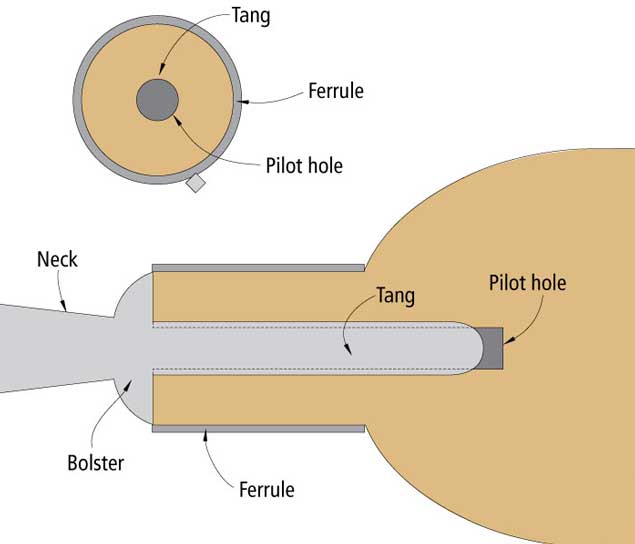

You possibly can flip a chisel deal with on a lathe in a couple of minutes. In case you don’t have a lathe, you possibly can form one with drawknife, spokeshave, aircraft or chisel nearly as shortly. Sounds easy. And for probably the most half, it’s. Most bench chisels are connected to their handles by a tang, as proven within the drawing. The one actual difficulties in rehandling a chisel contain making the pilot gap within the deal with for the tang. The opening have to be sized to make sure a good match with out splitting the deal with. And it should align the deal with and the blade on the identical axis. So, earlier than you slice off the handles of your favourite chisels for alternative, rehandle an identical, however much less valued, chisel (or two) for observe.

Off With the Previous

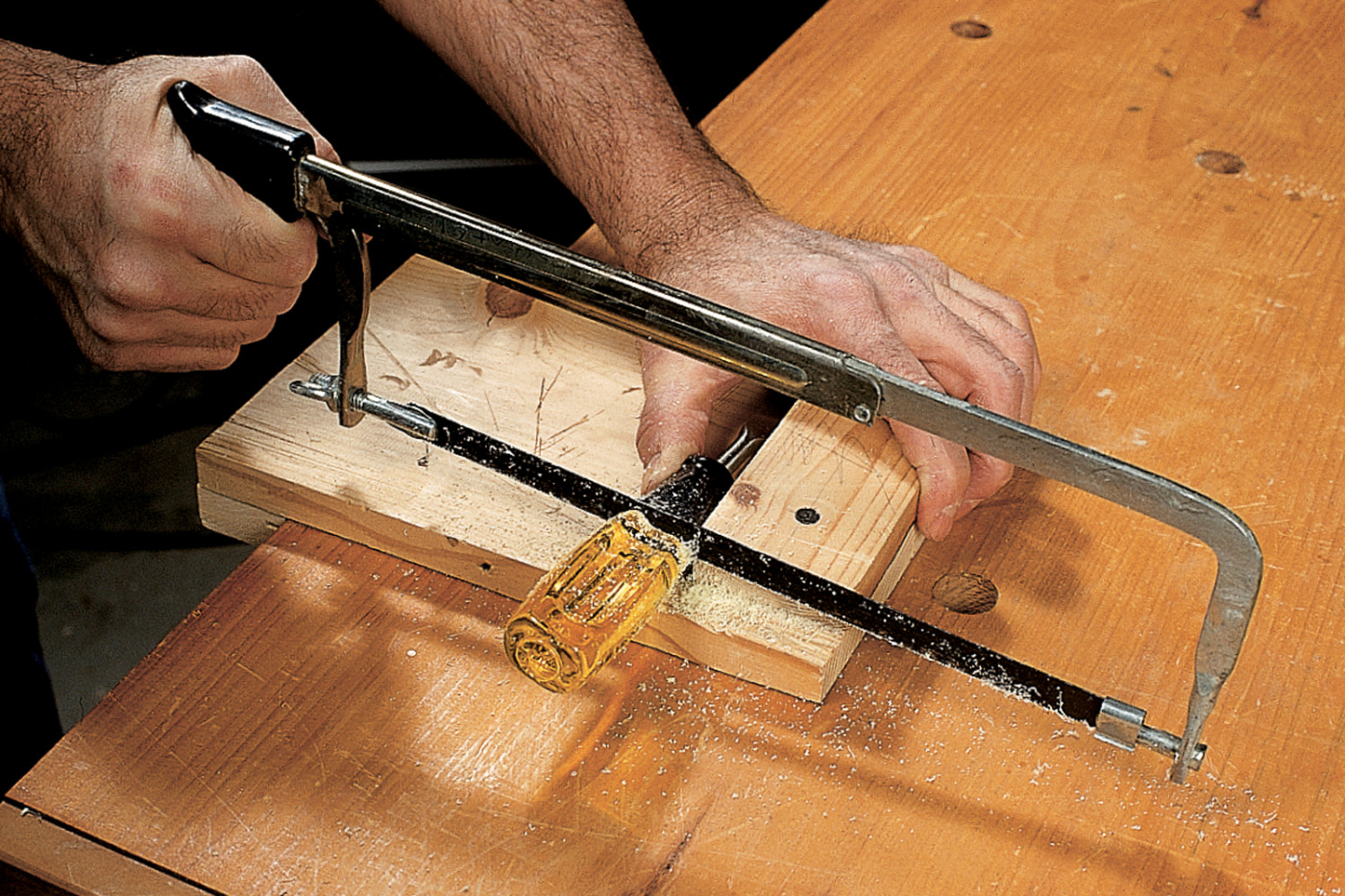

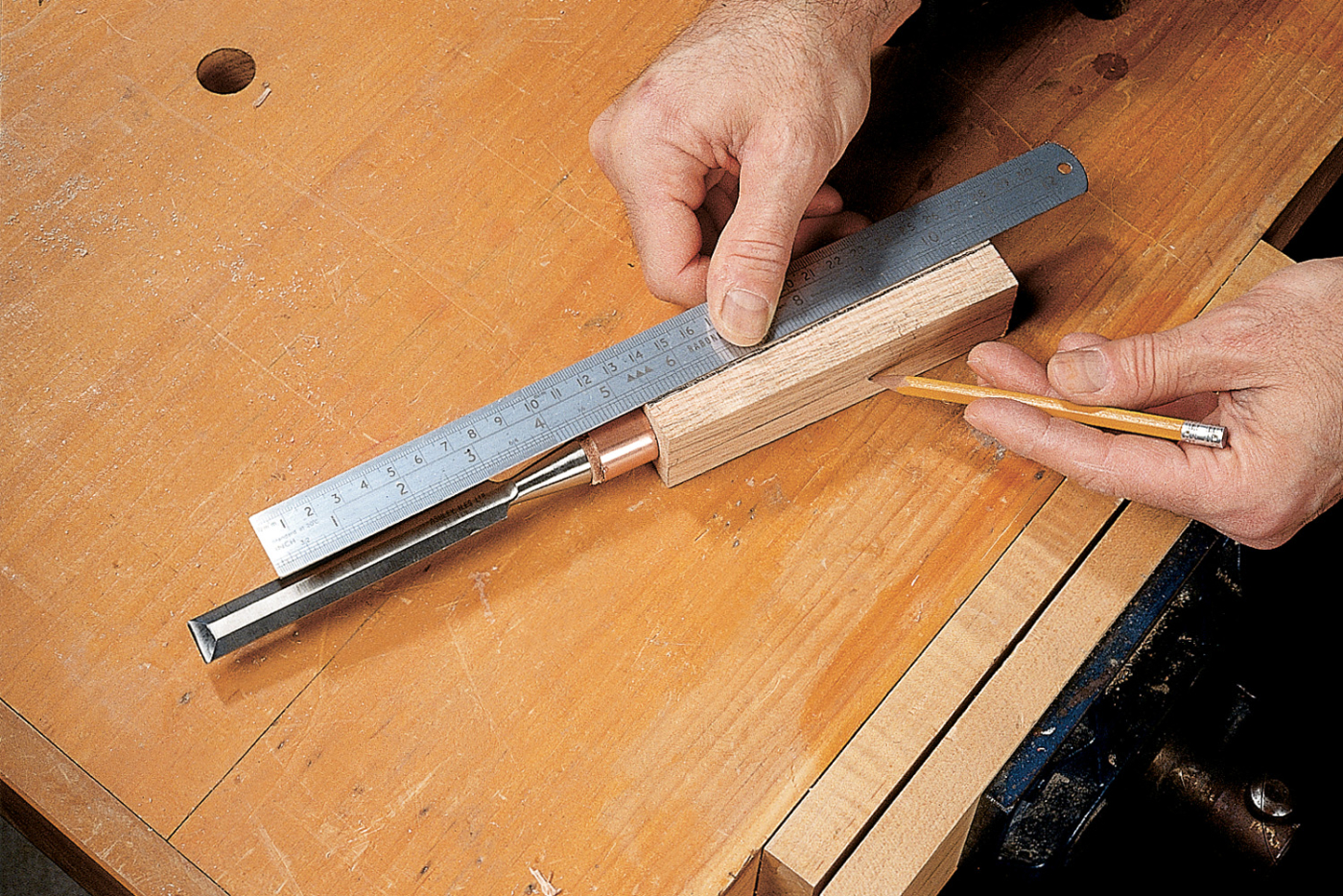

Earlier than you possibly can placed on a brand new deal with, it’s important to eliminate the previous one. First, mark the estimated size of the tang on the deal with – 2″ or so ought to do – then lower off the highest of the deal with above that time. I lower each composite and wooden handles with a hacksaw. If I’ve miscalculated the tang size, I gained’t destroy the enamel of my good backsaw.

Noticed off the highest of the previous deal with with a hacksaw – you gained’t harm the noticed enamel should you hit the tang by mistake.

In case you’re eradicating a wood deal with and also you wish to reuse the ferrule, subsequent make a number of noticed cuts simply above the ferrule all the way down to the tang. Then cut up away the rest of the deal with, utilizing one other chisel as a wedge. You could now be capable to drive the ferrule off the tang with a hammer and chilly chisel. Or it’s possible you’ll have to bore out a number of the wooden from contained in the ferrule to loosen it. In case you don’t wish to preserve the ferrule, simply lower by means of its size with the hacksaw and pry it off the tang.

After making noticed cuts on the high of the ferrule in to the tang, cut up a wood deal with away from the tang.

The method is analogous for a composite deal with, which is solid in place across the tang. Utilizing the hacksaw, I lower off the top of the deal with. Then I make lengthwise cuts all the way down to the tang to quarter the rest of the deal with, which makes it simpler to separate.

To take away a composite deal with, noticed lengthwise all the way down to the tang in three or 4 locations, then cut up the stays of the deal with from the tang.

Tang Varieties

Tangs on my previous chisels are four-sided and tapered to a degree. Some are irregular and bear the marks of forging. They’re seated within the deal with in a stepped pilot gap, as proven within the drawings additional down.

The chisel blade within the middle has a solid, four-sided tapered tang. The opposite blades have solid tangs. The left one, for a composite deal with, is cylindrical, with small “fins” alongside its size. The precise blade, for a wood deal with, has 4 faceted faces however no taper.

Tangs on a few of my newer chisels are solid, not solid. These for wood handles are faceted on 4 sides, however not tapered. They seat in a single pilot gap. The corners of tapered and faceted tangs dig into the wooden to make a good, torque-resistant match.

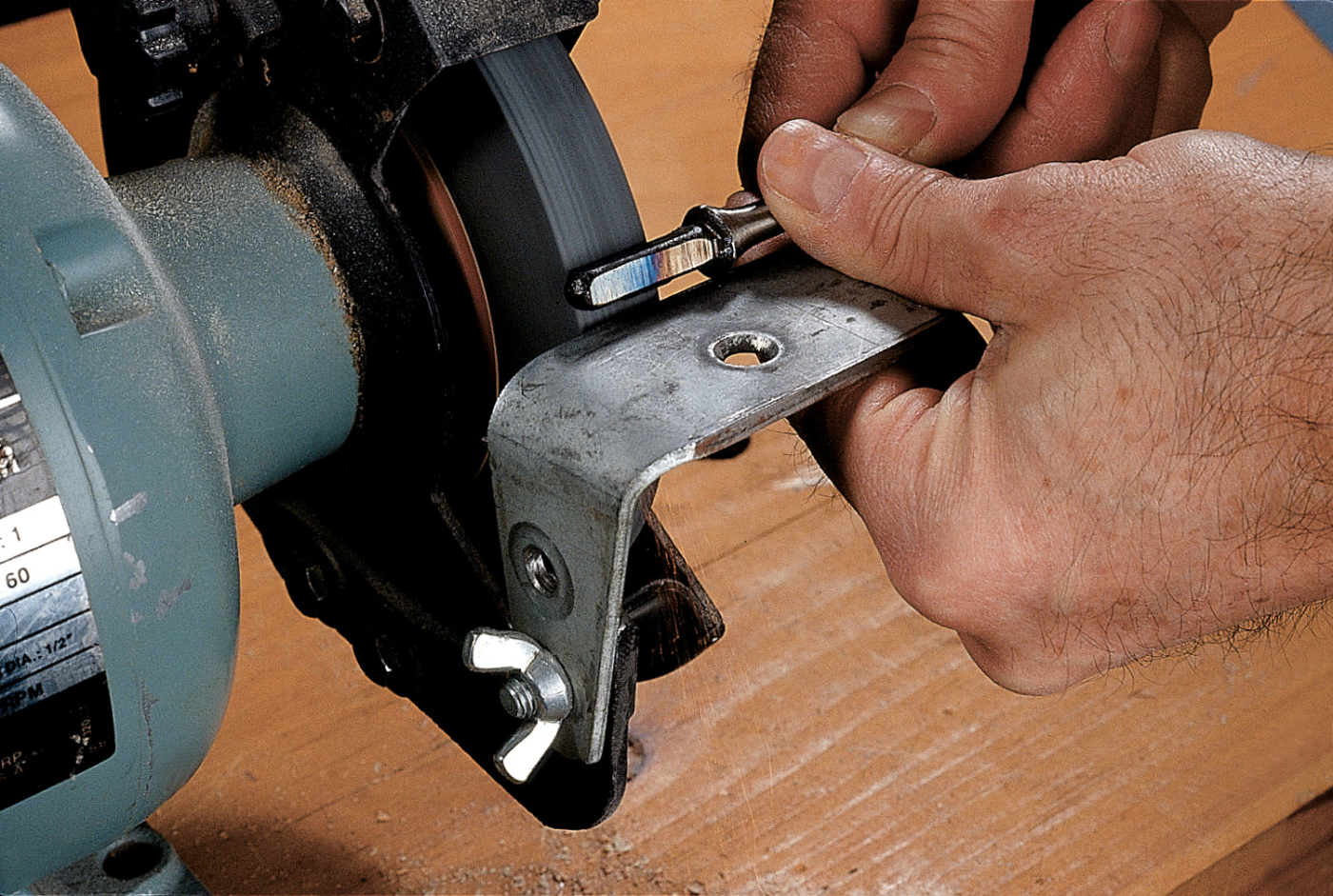

Tangs for my composite dealt with chisels are cylindrical, with small raised “fins” alongside their size to key them into the composite materials fashioned round them. Pushed right into a wood deal with bored to the identical diameter because the tang (or barely smaller), the fins may be sufficient to make sure a good match, notably for a light-duty chisel. I floor aspects on the tang and sized the pilot gap accordingly to be on the protected aspect.

Grind flat aspects on a spherical solid tang made for a composite deal with to make sure a good match within the new wood deal with.

To make sure that the sides of the tang dig into the wooden, the pilot gap must be smaller than the tang. For a square-section tapered tang, the bigger of the stepped pilot holes will be the identical diameter because the diagonal throughout the tang as measured about one quarter the size of the tang from the bolster. (The bolster is the flared part between the chisel’s slender neck and the tang; it seats in opposition to the top of the deal with.) Take the measure for the smaller gap about three-quarters of the size of the tang from the bolster. For an untapered faceted tang, make a single pilot gap of smaller diameter than the tang’s diagonal measure. The distinction within the measurement of the opening and the tang will be bigger in softer woods than tougher woods, which have much less give and can cut up extra simply.

Ferrules

These brief cylinders of brass or copper bind the deal with simply above the bolster of the chisel. The bolster and ferrule work collectively to stop the deal with from splitting when the chisel is pushed by a mallet. Chisels and gouges used solely with hand stress want no ferrules. However most chisels have ferrules even when they’re meant for wonderful paring work; some carving instruments don’t. For a lot of chisels, the best danger of splitting the deal with comes when becoming the deal with, so a ferrule is an effective precaution whatever the instrument’s meant use. Chisels and gouges subjected to heavy banging are sometimes fitted with a metallic hoop on the high of the chisel to stop splitting at that finish.

The scale of the tang and bolster largely decide the scale of the ferrule. In case you’re changing a wood deal with, you possibly can reuse the ferrule or use one the identical measurement. If you wish to match a smaller ferrule otherwise you’re changing a composite deal with, be sure there shall be sufficient wooden contained in the ferrule to accommodate the tang. Usually, the diameter of the ferrule have to be at the least that of the chisel’s bolster.

In case you don’t reuse a ferrule, you can also make your personal from copper tubing bought at {hardware} shops. Or you should buy brass ferrules for a number of cents apiece from Lee Valley Instruments. These are available in a wider vary of diameters than can be found in copper tube. You must match the deal with to the ferrule, so at all times have the ferrule you propose to make use of earlier than you make the deal with. Some chisels are fitted with leather-based washers that slip over the tang and seat between the bolster and the top of the deal with. I feel they’re meant by some means to cushion mallet blows, however I can’t say I really feel a distinction in use. I like them anyway, so I lower them out of a chunk of shoemaker’s sole leather-based and put them on.

Making the Deal with

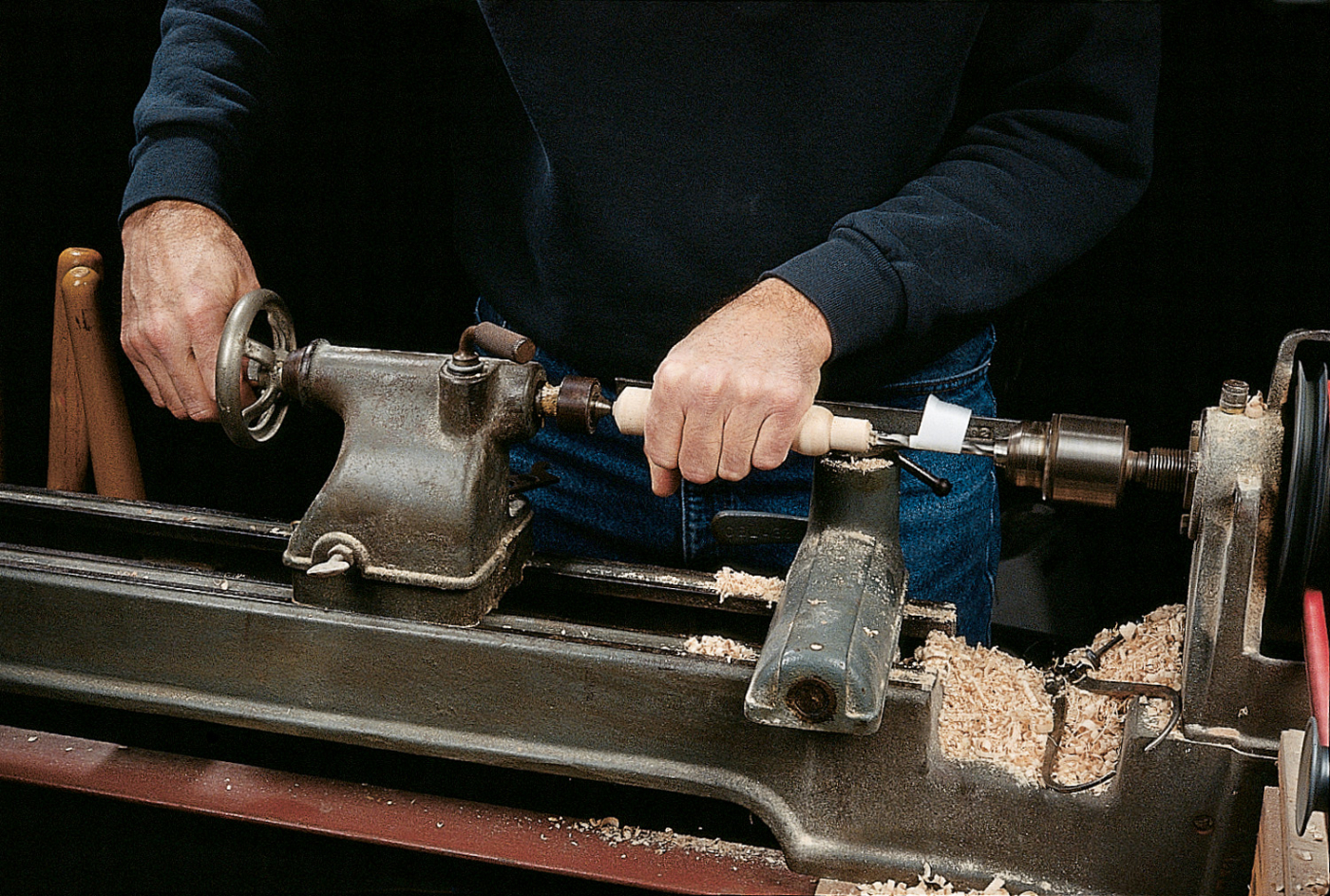

That is the enjoyable half. You can also make any form of deal with you possibly can think about. Turning handles on a lathe is fast and simple – you can also make and discard half a dozen earlier than you discover the one you need and nonetheless be performed in an hour. Shaping handles with drawknife, spokeshave, aircraft or chisels takes longer, however can produce deal with shapes – faceted or flattened for instance – which are unobtainable on a lathe. And you may mix turning and hand-shaping. If you wish to rehandle a chisel however don’t wish to make the deal with, you should buy a traditional boxwood sample in a number of sizes from Lee Valley.

You can also make handles in all kinds of shapes shortly and simply on a lathe.

Business handles are generally fabricated from ash, beech or boxwood. However any moderately exhausting wooden will do. I’m wanting ahead to creating some handles of osage orange, a local right here in Nebraska that has tight grain, a stunning orange shade, and is hard as nails. Firewood suppliers are wonderful sources of ash, maple, birch and different native woods that make wonderful handles. In case you can cut up deal with blanks from the log, you’ll be certain that the grain will run parallel to the deal with’s size, the strongest orientation.

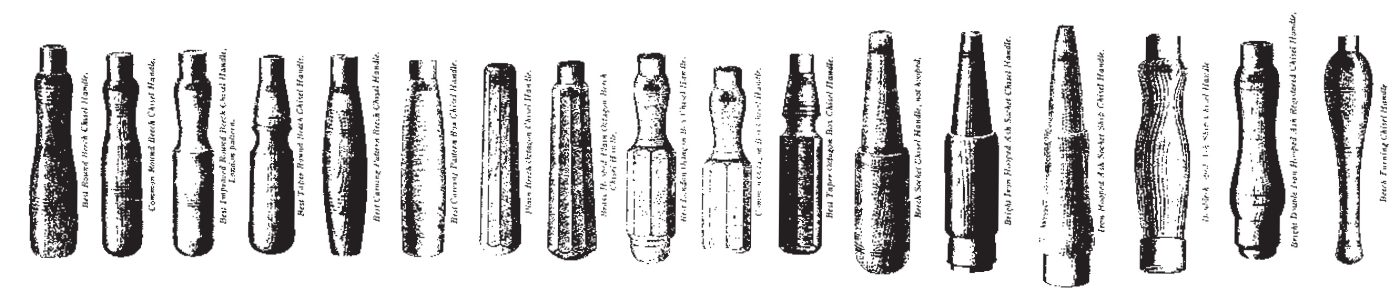

Completely different chisel handles as proven in R.A. Salaman’s “Dictionary of Woodworking Instruments” (Astragal Press), a wonderful useful resource on the identification and historical past of hand instruments.

On the Lathe

Turning is the best method to make a deal with. No matter form you select, you will need to match the ferrule snugly to 1 finish. It needn’t be a compelled match, however it shouldn’t rattle round on the wooden, both.

The good benefit of a lathe is in boring the pilot gap for the tang. I mount a chuck and bit on the pinnacle inventory and feed the deal with onto the bit by turning the tailstock’s dead-center wheel. This bores a gap proper on the deal with’s axis, making certain that the chisel blade and deal with shall be correctly aligned.

Bore the tang pilot gap on the lathe utilizing a machinist’s drill mounted in a chuck on the pinnacle inventory. Feed the deal with into the spinning bit with the feed wheel on the tail inventory.

Use machinist’s bits – the tapered nostril makes a neater, simpler entry than a brad level or different spur bit. Full the deal with’s form (and rub end on the spinning deal with with a fabric if you want) earlier than you bore the opening.

Seat the tang within the deal with by repeatedly putting the top of the deal with in opposition to an iron plate or machine desk.

Meeting

To hitch chisel and deal with, slip the ferrule in place on the top of the chisel deal with, add a leather-based washer if you’d like one and begin the tang within the pilot gap. You possibly can repair the chisel in a vise and drive the deal with on. I choose to upend the chisel and deal with and bang the top of the deal with on a machine desk or different heavy piece of iron. Accomplished this fashion, the blade’s personal weight drives the tang into the deal with and I don’t have to fret concerning the blade slipping within the vise. It takes some time, however until you’ve badly underestimated the scale of the pilot gap, the bolster will finally seat snugly in opposition to the top of the deal with. Even when the opening is a bit too tight, splits are normally contained by the ferrule.

Hand-shaping a Deal with

In case you don’t have a lathe, otherwise you desire a faceted deal with, it’s simple to form one by hand. The tough half is boring the pilot gap within the deal with in order that the blade and deal with shall be aligned. A blade that skews off the deal with centerline will be very awkward to make use of. I feel the best methodology is to bore the opening in a sq. deal with clean earlier than shaping the deal with. With a drill press the opening will be bored very precisely. Or the clean will be held firmly in a vise for hand drilling. Set a sq. or two as much as gauge the angles.

After making cuts on the nook to stop splitting alongside the deal with’s whole size, kind the ferrule seat with a chisel.

In case you’re unsure concerning the alignment of the tang pilot gap and deal with, you possibly can assemble the blade to the deal with clean.

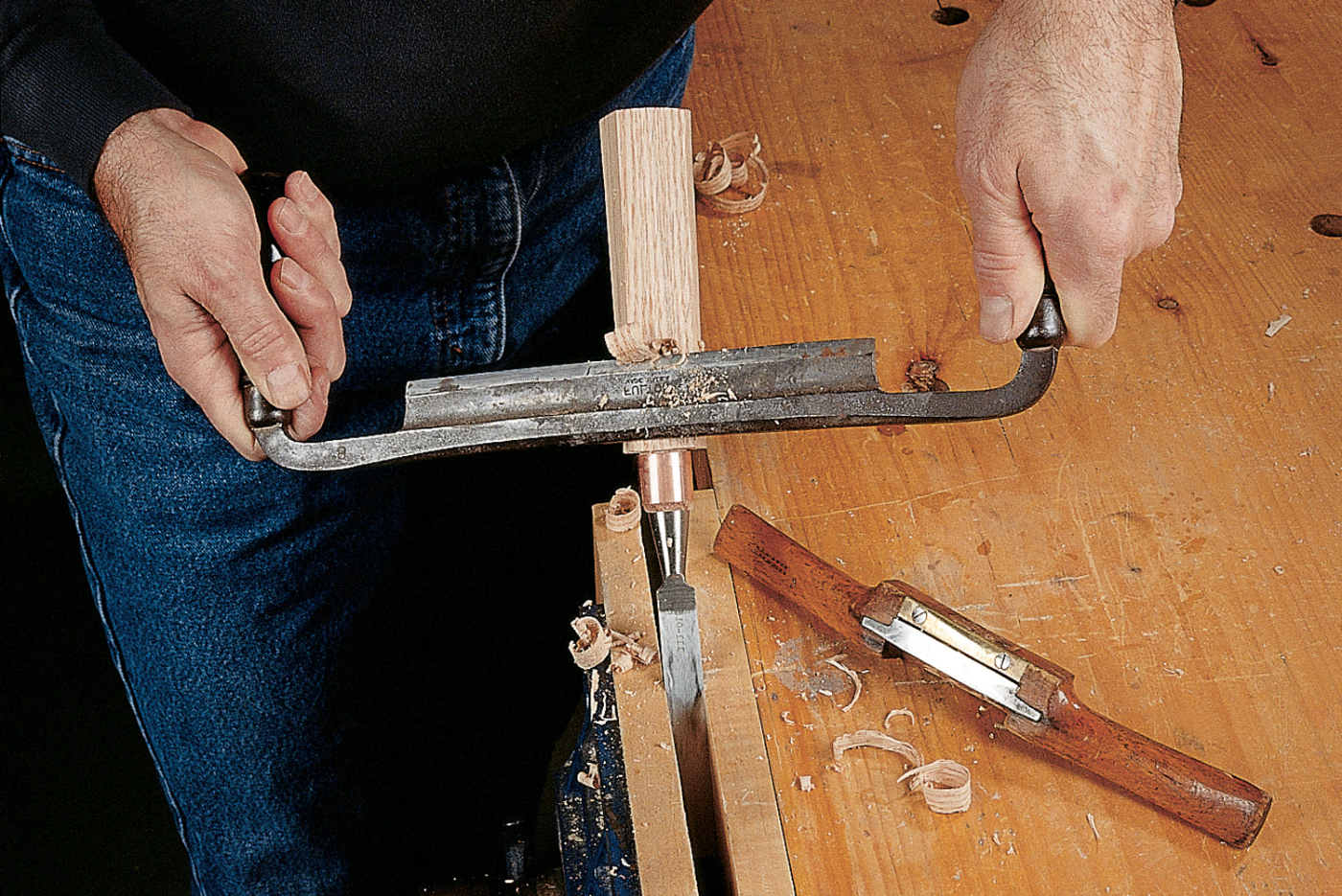

Subsequent, kind the seat for the ferrule. Make noticed cuts in at every nook to stop splitting past the ferrule seat. Then pare rigorously with a chisel till the ferrule matches the seat snugly. In case you’re assured that the pilot gap is effectively centered alongside the size of the clean, you possibly can form the deal with, then assemble it with ferrule and blade as described beforehand. In case you’re unsure concerning the orientation of the pilot gap, you possibly can assemble the deal with and blade, then form with drawknife and spokeshaves, as proven within the pictures. This could be a bit awkward in spots, however it permits you to make changes within the deal with to offset an off-center pilot gap.

Draw traces on the deal with alongside the axes of the blade.

Form the deal with parallel to the axes to make sure good blade-handle alignment.

Rehandling a chisel or gouge could be very satisfying. A selfmade deal with is probably not stronger or extra sturdy than one from the manufacturing facility. However it’s actually extra private and is value doing for that purpose alone.

Product Suggestions

Listed here are some provides and instruments we discover important in our on a regular basis work across the store. We might obtain a fee from gross sales referred by our hyperlinks; nonetheless, we’ve got rigorously chosen these merchandise for his or her usefulness and high quality.