In contrast to most woodworking tasks, audio system require a information of audio elements and a selected method to materials choice and joinery. For those who select to make your personal audio system, although, you’ll find yourself with superior efficiency at a a lot decrease value than for those who purchase them off the shelf. And they are going to be rather more enticing. Comply with alongside as Andrew Gibson tells you what it’s worthwhile to know, from the particular elements it’s worthwhile to the ins and outs of designing for the most effective sound.

As a furnishings maker and luthier with a ardour for music, I’ve had quite a lot of enjoyable constructing my very own audio elements, particularly audio system. These tasks have given me the possibility to study quite a few new expertise and ideas. Audio system require a novel method to materials choice, hermetic joinery, and cautious soldering.

What makes these high-end DIY audio system doable is the vary of outlets promoting wonderful components kits. These kits embrace the audio system themselves (drivers) and the entire electrical/digital components you’ll want, together with detailed directions on learn how to assemble them and construct the containers. My favourite retailers embrace DIY Sound Group, GR-Analysis, and Elements Categorical.

The kits we selected for this text embrace solely {the electrical} elements, leaving the purchasers to construct the containers. Whereas many corporations additionally provide precut field components, to be glued up and completed as desired, these take away a part of the enjoyable for me.

Go along with a components package

In case you have a deep curiosity in electronics and acoustics, you’ll be able to choose and buy the drivers, crossovers, wires, capacitors, and different electronics individually. For many of us, nonetheless, a high-quality components package is the best way to go. These be certain that elements are matched correctly, and so they embrace directions for a correctly designed speaker field, one other essential element.

Extra sound for much less—I’ve constructed quite a few audio system utilizing components kits like those cited under, and in every case the audio system I constructed carry out significantly better than premade audio system offered at an analogous value.

For instance, to get audio high quality much like that produced by the high-end bookshelf audio system featured on this article—constructed utilizing a $400 element package from GR-Analysis—you’d seemingly must spend $1,000 or extra on off-the-shelf audio system. Actually, that’s what GR-Analysis expenses for a accomplished pair utilizing the identical package.

Whereas there are even higher-level kits accessible, priced into the hundreds for true audiophiles, the X-Bravo package I used produces audio system that pair properly with high-end audio elements and/or a home-entertainment system.

With all however essentially the most primary speaker kits, some soldering is concerned. However don’t be intimidated; this sort of soldering requires quite simple instruments and is simple to study.

Stable development method for many audio system

As a result of the digital elements in these kits have been rigorously matched to one another, we don’t have to fret about their design or compatibility. However the speaker containers are one other story.

I went with the precise inner sizes really useful by the designers who put the components kits collectively. I additionally adopted a few of their suggestions for supplies and joinery. That also left me loads of room so as to add {custom} touches that make the audio system appear like superb woodworking.

Whether or not custom-built or bought, speaker containers should be hermetic. That’s tough to do with stable wooden, which shrinks and expands. The containers additionally should be robust and stiff. If a field resonates like a guitar, it can take in among the drivers’ vitality and trigger distortion.

To construct hermetic containers with as little resonance as doable, I used MDF lined with shopsawn veneer. MDF is a perfect substrate for veneering, and it has nice acoustic properties for audio system. Fortunately, our audio system are sufficiently small that standard clamps, used at the side of MDF clamping cauls, will work nice for making use of the veneer. So that you received’t want a vacuum bag.

Veneer the panels

Use a contemporary blade, at the very least 3/8 in. huge, with three or fewer tooth per inch, and heart it on the higher wheel. Noticed the veneers somewhat over 1/8 in. thick.

To create wider veneers, be part of strips. Stretch blue tape throughout one facet of the joint, fold the joint open, unfold glue on the sides, fold the panel flat once more, after which stretch tape throughout the opposite facet.

After the glue has cured, airplane each side evenly, bringing the panel right down to 7/8 in. thick within the course of. Use the desk noticed to wash up the sides.

Construct the field components

To affix the veneered components, I favor mitered corners with glued-in back and front panels. The mitered corners be part of the veneered components seamlessly, and the MDF substrate lets me glue the back and front panels into rabbets or grooves with out having to fret about enlargement.

Reduce the components to actual dimension, and use a crosscut sled to chop the miters. Use a cease block to make sure that the cuts finish proper on the edges of the workpiece.

Dry-fit the edges with blue tape, and trim the back and front panels till they drop into their rabbets.

To assemble the miter joints, I glued on angled clamping blocks, which I sawed and sanded off after meeting. It might have been straightforward to sand by skinny veneers, however that hazard was eradicated with shopsawn veneers.

Reduce the openings

The back and front panels want openings of varied shapes, relying on the speaker design. For those who can’t lower them with a Forstner drill bit, use a router and template to do the job.

Make a template for the driving force holes. Drivers want massive holes, generally rabbeted. Use a circle cutter within the drill press to make templates, factoring within the offset between the router bit and the information bushing you’ll be utilizing.

The smaller driver wants a rabbeted gap, which is notched. So this template has two totally different circles for routing the identical driver gap. Place a sacrificial board underneath the workpiece, and use double-stick tape to connect the template in every place.

End up the field

After the field is glued up, the back and front edges are rabbeted to just accept solid-wood strips, that are rounded on the router desk.

After stretching blue tape throughout the joints, Gibson makes use of CA glue to connect 45° MDF blocks. Maintain each in place for 15 seconds earlier than shifting on.

To stiffen the field, the X-Bravo design features a dowel that connects one facet to the opposite. Drill for this dowel forward of time, and insert it throughout meeting.

Unfold yellow glue on the miter joints, shut up the field, and tape the final nook closed. Then unfold glue within the rabbets, add the back and front panels, and clamp frivolously throughout the miter joints. Add extra clamps to tighten the panels of their rabbets.

After meeting, the back and front edges get a 3/8-in.-sq. rabbet for stable nook strips.

Glue within the nook strips. These are lower a bit thicker than 3/8 in. Dry-fit them to dial within the miter joints, and fasten them with glue and blue tape.

After the glue dries, airplane and/or sand the strips flush, and use a 3/8-in. roundover bit to spherical them.

Construct the crossover

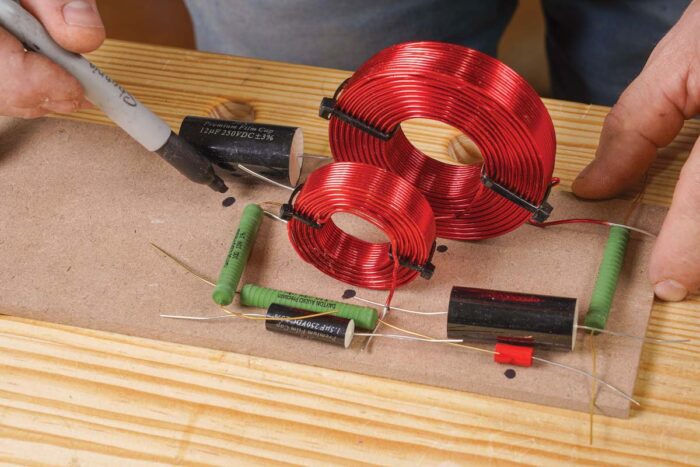

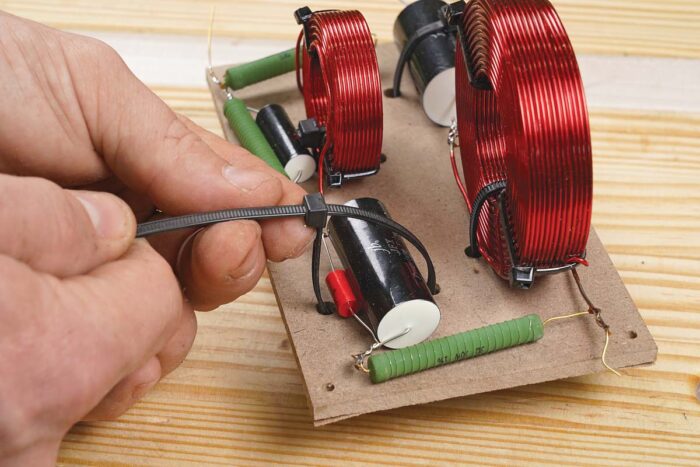

Reduce a bit of 1/4-in. MDF slender sufficient to suit into the big driver gap, and skim the X-Bravo directions to grasp how the components ought to be organized and linked. Place the components as tightly as doable, and mark and drill holes for zip ties.

Twist the wires as proven, add flux, and solder the joints. The solder ought to move alongside your complete joint. Verify the alternative web page for extra soldering recommendation.

As soon as their joints are soldered, lock down the primary components with zip ties that cross by holes within the base board.

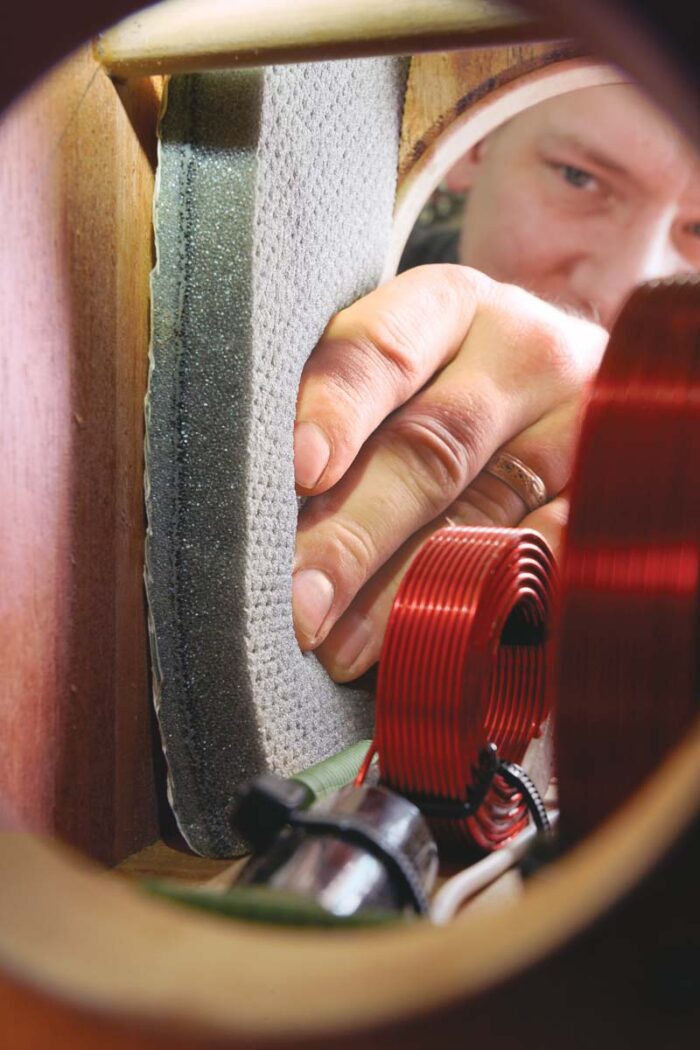

The panel slips by the bigger driver gap and is screwed to the underside of the speaker field.

Ending touches

As soon as the containers and crossovers are carried out, the remainder is simple.

This self-adhesive acoustic foam (from Elements Categorical) strains the field to forestall echoes

inside. It’s best to place the items with the backer connected after which peel it off with the

items in place.

Depart the speaker wires extralong, and solder them to the drivers. Then screw the drivers rigorously in place. Drill pilot holes that will help you keep away from slipping with the screwdriver and puncturing the driving force cones.

The port is solely pressed into its gap, and the speaker-wire cup is screwed in place.

Self-adhesive felt circles are all it takes to maintain audio system from rattling, however these speaker ft look and carry out even higher.

|

|

-Andrew Gibson is an teacher on the Florida Faculty of Woodwork in Tampa, Fla.

Join eletters right this moment and get the most recent methods and how-to from High-quality Woodworking, plus particular presents.

Obtain FREE PDF

once you enter your electronic mail handle under.