We might obtain a fee while you use our affiliate hyperlinks. Nonetheless, this doesn’t impression our suggestions.

Decide your bit. All of those bits can drill holes in wooden – so which must you select? From left are pictured a Forstner bit, twist bit, brad-point bit and spade bit.

Uncover a bit about clear, correct boring.

Tlisted here are many instruments in trendy woodworking you should utilize to bore holes: powered drills (each corded and cordless), drill presses, hand-powered eggbeater drills, braces and extra.

Drill presses are the powered technique of alternative when accuracy is essential. Battery-operated drills are handy and quick. Corded drills are quick, by no means want charging and are often lighter in weight than their battery-powered brethren. Eggbeater drills are superior while you want only a few holes. Braces are perfect for drilling large-diameter holes with ease, and making holes at odd angles (as in chairmaking) with out a number of loopy jiggery.

It’s Fundamentals Week 2024! Use the code Basics25 to save lots of 25% off your first month or full yr of PopWood+.

Auger Bits

Two frequent patterns. The Irwin-pattern bit (high) has extra broadly spaced flutes than the Jennings-pattern bit. Observe, too, the distinction within the lead screws. The coarse lead screw on this Irwin is for softwood; the positive thread on this Jennings is for hardwood.

Auger bits are utilized in a brace and are available in two frequent patterns: Irwin (high) and Jennings. Each have self-feeding lead screws to assist find the minimize and drill a lead gap; lead screws on each are available in three iterations: positive (hardwoods), medium (exhausting and softwoods) and coarse (softwoods). Each patterns have two sharp spurs to attain the circumference and two chopping lips to bore the outlet. Not like the Jennings, the Irwin has a stable central shaft; for each three spirals within the minimize for the Jennings there are two spirals for the Irwin. The latter is much less prone to clog when boring deep holes – however as a consequence of its wider spiral spacing, it’s extra seemingly the start borer will ream a gap whereas chopping. Like all bits, augers have to be stored sharp and rust-free to work effectively. They’re sometimes obtainable in 1⁄4“-1” diameter.

Twist Bits

These bits are designed to chop steel, however are generally and efficiently used on wooden, too. It may be tough to get a twist bit began in a exact location and it might observe the grain within the minimize. To fight that, use an axe or different pointy software to start out a gap precisely the place desired. Twist bits could cause splintering, notably on the bottom of labor.

These bits are designed to chop steel, however are generally and efficiently used on wooden, too. It may be tough to get a twist bit began in a exact location and it might observe the grain within the minimize. To fight that, use an axe or different pointy software to start out a gap precisely the place desired. Twist bits could cause splintering, notably on the bottom of labor.

■ Widespread sizes: 1⁄32“- 5⁄8“

Brad Level Bits

These are the only option for many small-diameter holes in woodworking. The brad level lets you find the bit exactly, and retains it from wandering. The spurs on the tip minimize a cleaner gap and scale back splintering each on the entry and bottom. (Additionally, bit sizes as much as about 1⁄4” may be use with eggbeater drills).

These are the only option for many small-diameter holes in woodworking. The brad level lets you find the bit exactly, and retains it from wandering. The spurs on the tip minimize a cleaner gap and scale back splintering each on the entry and bottom. (Additionally, bit sizes as much as about 1⁄4” may be use with eggbeater drills).

■ Widespread sizes: 1⁄16“- 5⁄8“

Spade Bits

These bits are finest for hogging out waste rapidly when a clear gap shouldn’t be a problem; they often trigger unhealthy splintering, notably on the bottom of a workpiece (and a few splintering on the entrance) – although scribing the minimize first in reverse alleviates this to a point. Cheap spade bits may be simply floor for customized sizes.

These bits are finest for hogging out waste rapidly when a clear gap shouldn’t be a problem; they often trigger unhealthy splintering, notably on the bottom of a workpiece (and a few splintering on the entrance) – although scribing the minimize first in reverse alleviates this to a point. Cheap spade bits may be simply floor for customized sizes.

■ Widespread sizes: 1⁄4“- 1-1⁄2“

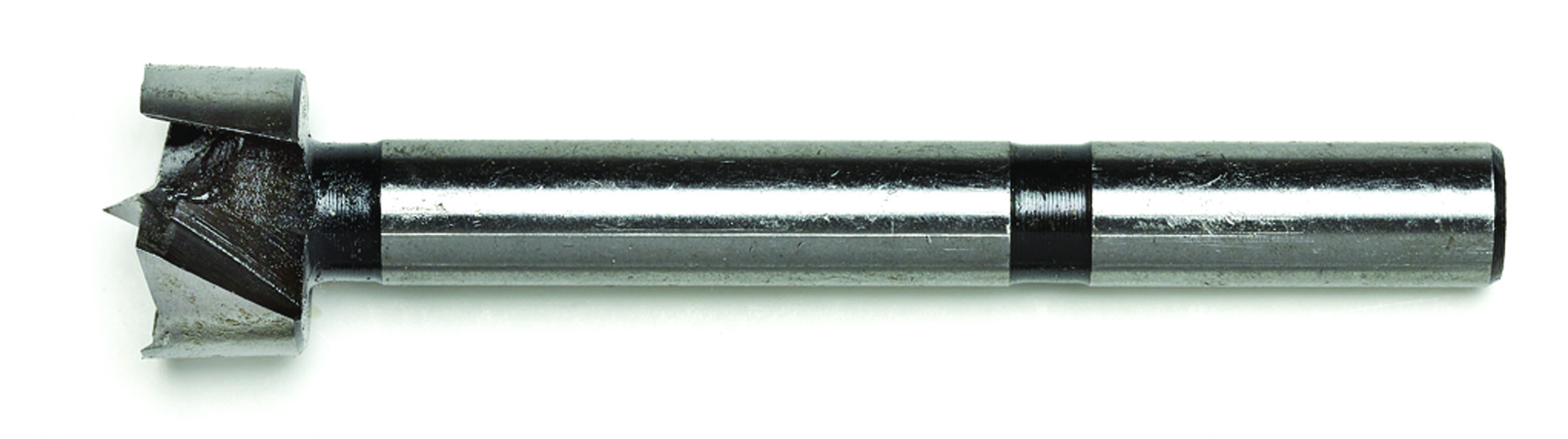

Forstner Bits

These bits minimize clear, correct flat-bottomed holes in bigger diameters. The lipped edges shear materials to cleanly outline a gap’s edge and the middle level makes it easy to find the outlet’s heart. Because of the drive wanted to make the minimize, Forstner bits are finest utilized in a drill press or brace.

These bits minimize clear, correct flat-bottomed holes in bigger diameters. The lipped edges shear materials to cleanly outline a gap’s edge and the middle level makes it easy to find the outlet’s heart. Because of the drive wanted to make the minimize, Forstner bits are finest utilized in a drill press or brace.

■ Widespread sizes: 5⁄16“- 2”

Degree & Plumb

A drill press excels at boring correct holes at a predetermined angle – however so are you able to; it simply takes a bit apply. I assume the vast majority of starting woodworkers use an electrical drill – so let’s take into account the right grip.

Like a handsaw or handplane, a drill is finest used with a three-fingered grip. Use your center finger to depress the set off; your index finger ought to level alongside the aspect of the software, within the course that you’re drilling. Your pointing finger helps to cue your physique to move in the identical course. I understand it sounds a bit bit nutty – however strive it out; you’ll uncover it really works for nearly any software that you just grip with one hand.

It’s additionally essential to appreciate that for a lot of holes, there’s a important and non-critical axis, and to align your software and physique on the important axis.

Let’s use clearing waste from a mortise for instance. Wanting from the top of the workpiece, what’s essential is that you just don’t let the bit record aspect to aspect; entrance to again is OK (besides on the ends). Thus, aspect to aspect is the “important axis.”

Sight your bit in opposition to a strive sq. centered on the far finish of the mortise (or draw a centerline past the top of the mortise to information you), and align your physique in entrance that information. The strive sq. or line, alongside along with your physique place, will provide help to maintain the software within the important axis.

Lower a Clear Gap

When you want a gap in a present floor and are frightened about splintering, again up the minimize with a chunk of scrap (you can even apply a chunk of painter’s tape atop the outlet location earlier than deploying the drill, which is reasonably efficient). Higher but, scribe the minimize first by slowly transferring the bit in reverse by hand – or, if on the drill press, by reducing the bit onto the wooden then rotating the workpiece.

Pilot Gap vs. Clearance Gap

You’ve no-doubt seen the instruction to “drill a pilot gap.” That’s merely a small gap centered within the minimize to assist paved the way for what comes subsequent – a larger-diameter gap, a nail or a screw. A pilot gap is tight sufficient that the subsequent bit (or {hardware}) cuts into the outlet’s partitions.

A clearance gap, nevertheless, clears a large path for what follows, equivalent to a bolt, or a screw by means of the highest of two boards being joined collectively.

Conclusion

That is clearly not the entire story on bits and boring – however I hope it’s sufficient to get you began on the trail to drilling success.

Product Suggestions

Listed here are some provides and instruments we discover important in our on a regular basis work across the store. We might obtain a fee from gross sales referred by our hyperlinks; nevertheless, we now have rigorously chosen these merchandise for his or her usefulness and high quality.